Fuel consumption meter test

Flowtronic System

Device mainly used for fuel consumption measurement of internal combustion engines (for basic fuel types such as gasoline, diesel, biofuel and alcohol). Their use covers motorcycles, passenger cars, buses, vans, special purpose vehicles and ships. It can be used both in moving vehicles and in stationary bench tests. The Flowtronic system is suitable for the consumption measurement of many types of liquid fuels due to its simple operation, robust construction, high measurement accuracy and unique quality.The latest generation of updated products has targeted upgrades to the corrosion resistance of methanol fuel, allowing for long-term testing.

Sensor S8005C

The small S8005C is a general-purpose flow sensor, which can be applied to various types of engine systems with only oil supply circuit and no oil return circuit. It allows for simple and quick installation, for example in the engine compartment. All sensors use quick self-locking connectors, making installation and operation very fast. According to the needs of customers, quick-lock anti-spill joints can be selected to achieve fast operation.

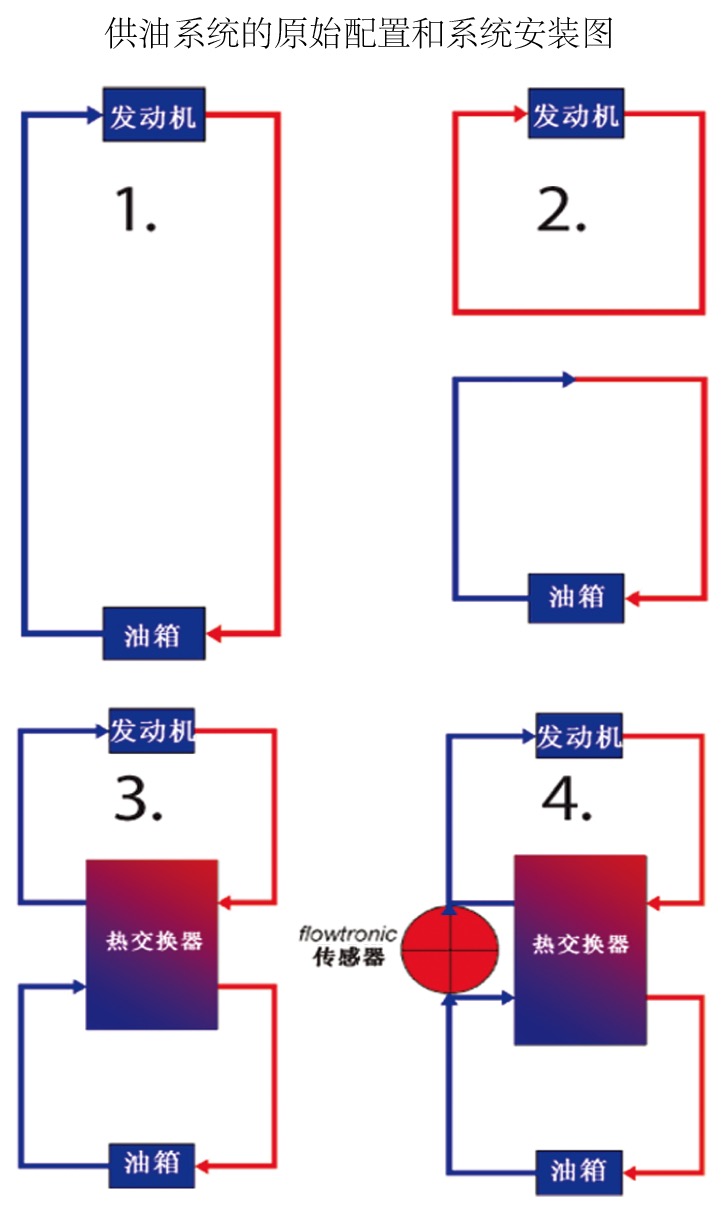

Expansion system for S8005C sensor and HE8005 heat exchanger

For engine systems that have both a supply circuit from the tank to the engine and a return circuit back to the tank, we need to use the HE8005 heat exchanger. Using the HE8005 heat exchanger, the original fuel supply system was divided into two separate fuel circuits. One of the two fuel circuits is a circuit associated with the engine, and the other is a separate circuit associated with the fuel tank. In addition, the heat exchanger also serves to cool the fuel between the two loops. This prevents the fuel in the circuit associated with the engine from becoming too hot to bubble up.

This Flowtronic system, based on several modules, such as sensors, heat exchangers and, if required, a pressure regulator, can be used in many types of engine systems, including fuel systems where the fuel supply pump is mounted in the tank or a A system where the pump is mounted on the engine end. The permissible circulating flow of the system is a maximum of 150 to 170 l/h. An optional pressure regulator can be used to manually control the fuel pressure in the fuel supply circuit. However, it cannot control the fuel pressure in the return circuit.

A Great Alternative to Kistler CDFL1A and CDFL3A

The Flowtronic S8005C is a perfect replacement for the Kistler CDFL1A;

The Flowtronic S8005C & HE8005 is a perfect replacement for the Kistler CDFL3A.

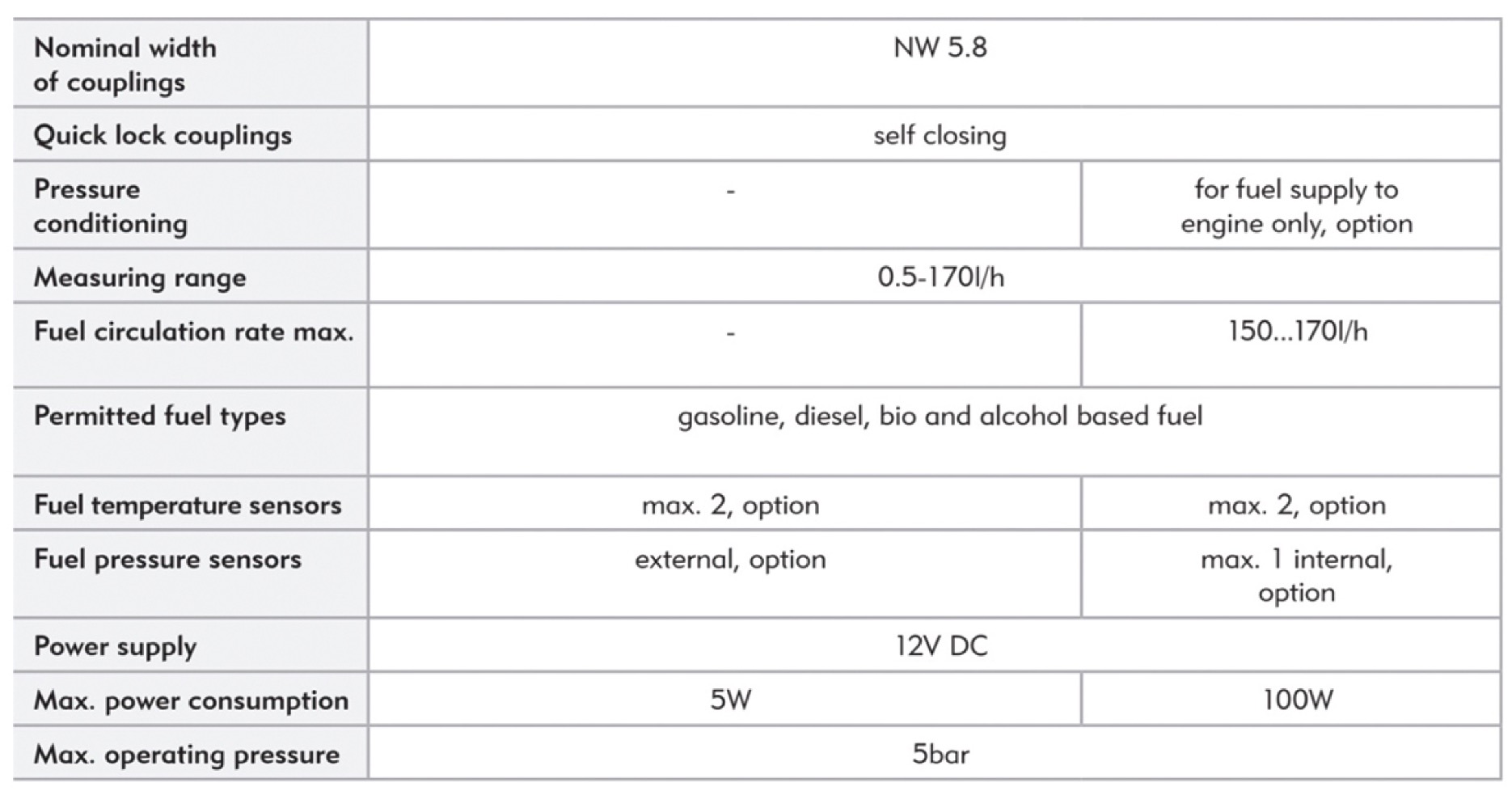

Below is a technical specifications comparison table:

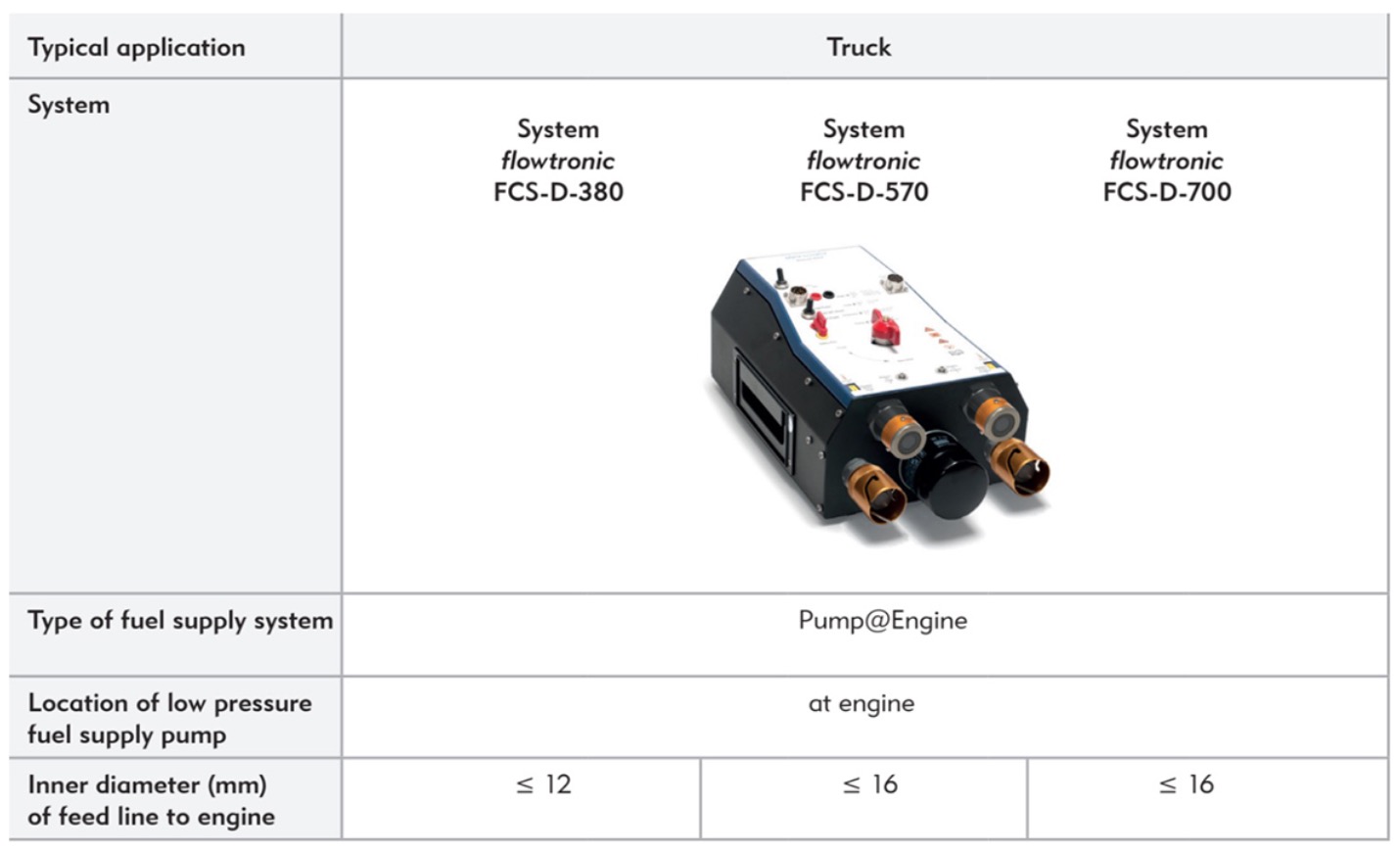

FCS-D-380/-570/-700 Systems

These systems are specifically designed for diesel engines, where the low pressure fuel supply pump of the engine is installed at one end of the engine (because the pressure of the fuel supply is lower). The unit integrates a built-in heat exchanger and optionally up to two built-in thermocouples to measure the temperature of the fuel. Connection in current fuel supply systems is as simple as connecting via four quick-lock anti-spill connections. Adapter for quick and easy connection to the fuel line of the original fuel supply system, supplied as standard by the factory.

The integrated system control electronic unit can prompt the status of the system through LEDs in case of excessive voltage, reverse connection of the positive and negative poles of the power supply, and temperature exceeding the allowable range. quick shutdown function. Therefore, this series of products has a high product protection function.

Signal Conditioning Unit

System operation requires an SCU8005D or S8005AD-2 signal conditioning unit. The technical characteristics of the two units are different.

S8005AD-2

The Signal Conditioning Unit S8005AD-2 is used to connect the Flowtronic system to an external existing data acquisition system, it is part of the sensor system. Signal output status includes fuel volume (TTL) and flow rate (analog), as well as system status via LED.

SCU8005D

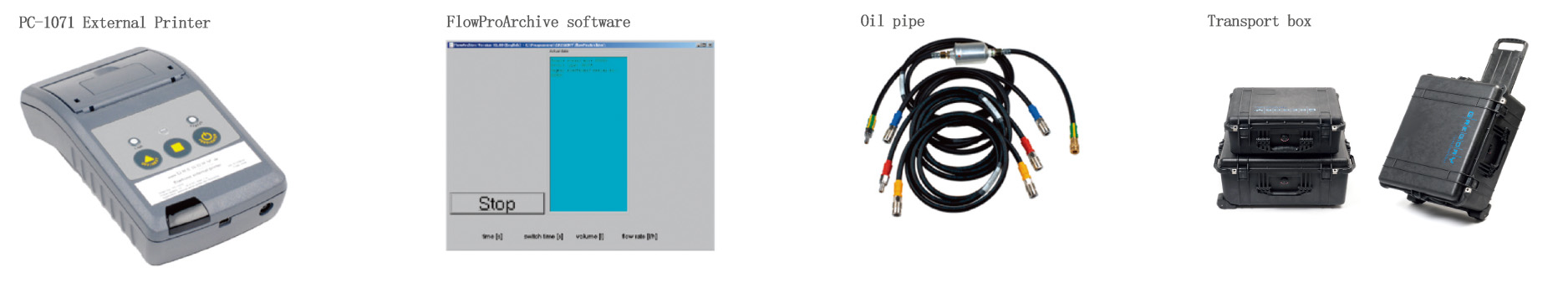

SCU8005D provides more functions: user interface language can be selected from German, English and Chinese, new accelerated fuel consumption measurement function, integrated system software, black and white touch screen display, display data and operation data output to external notebook or desktop . The external printer will print out the test data results in time at the end of the fuel consumption test. Stable and adjustable suction cups can be fixed to the front windshield.

Dual pulse output (optional)

Provide dual pulse output options to ensure accurate signal recording.

Other accessories

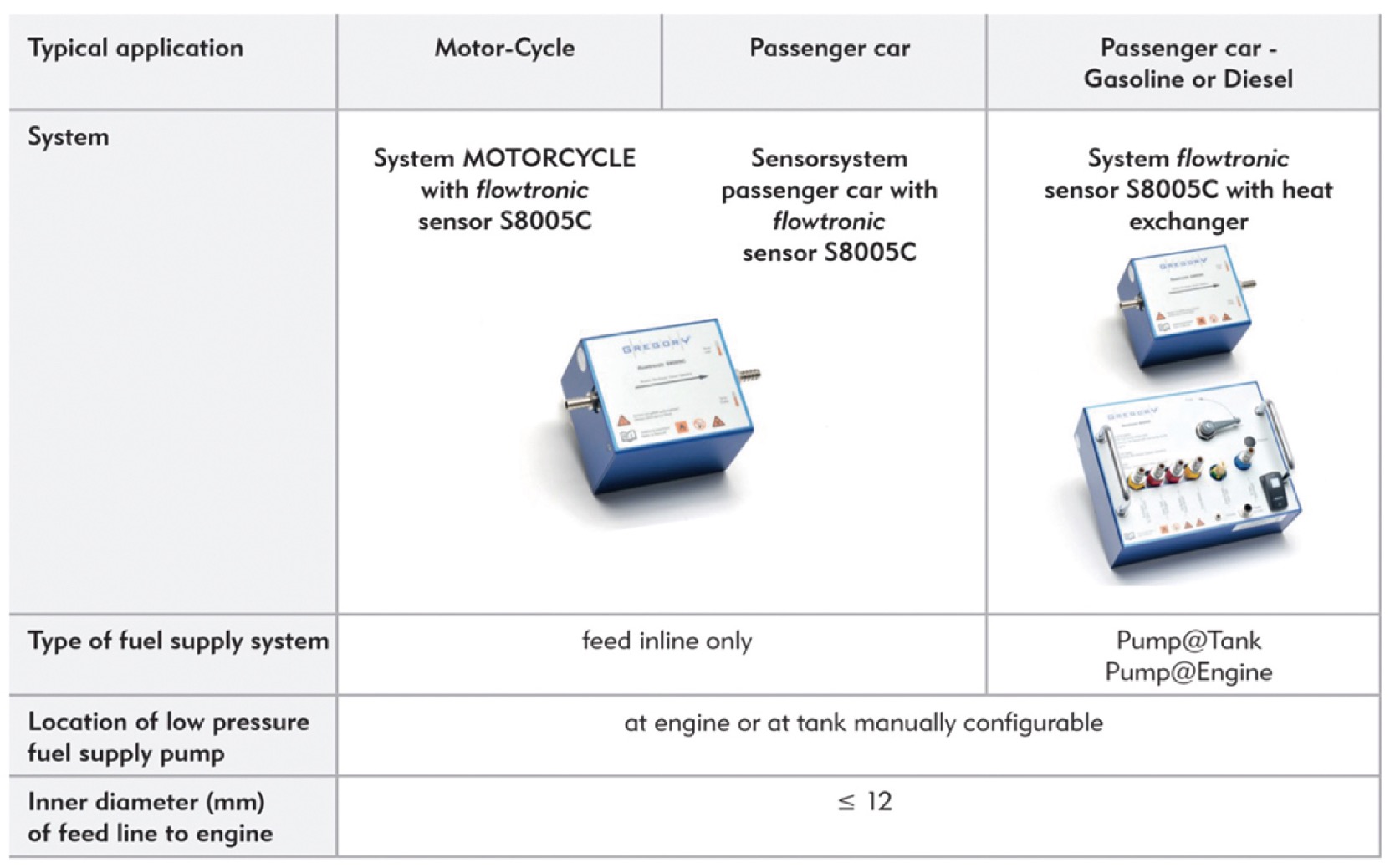

System Selection Table (S8005C)

Technical Parameters(S8005C)

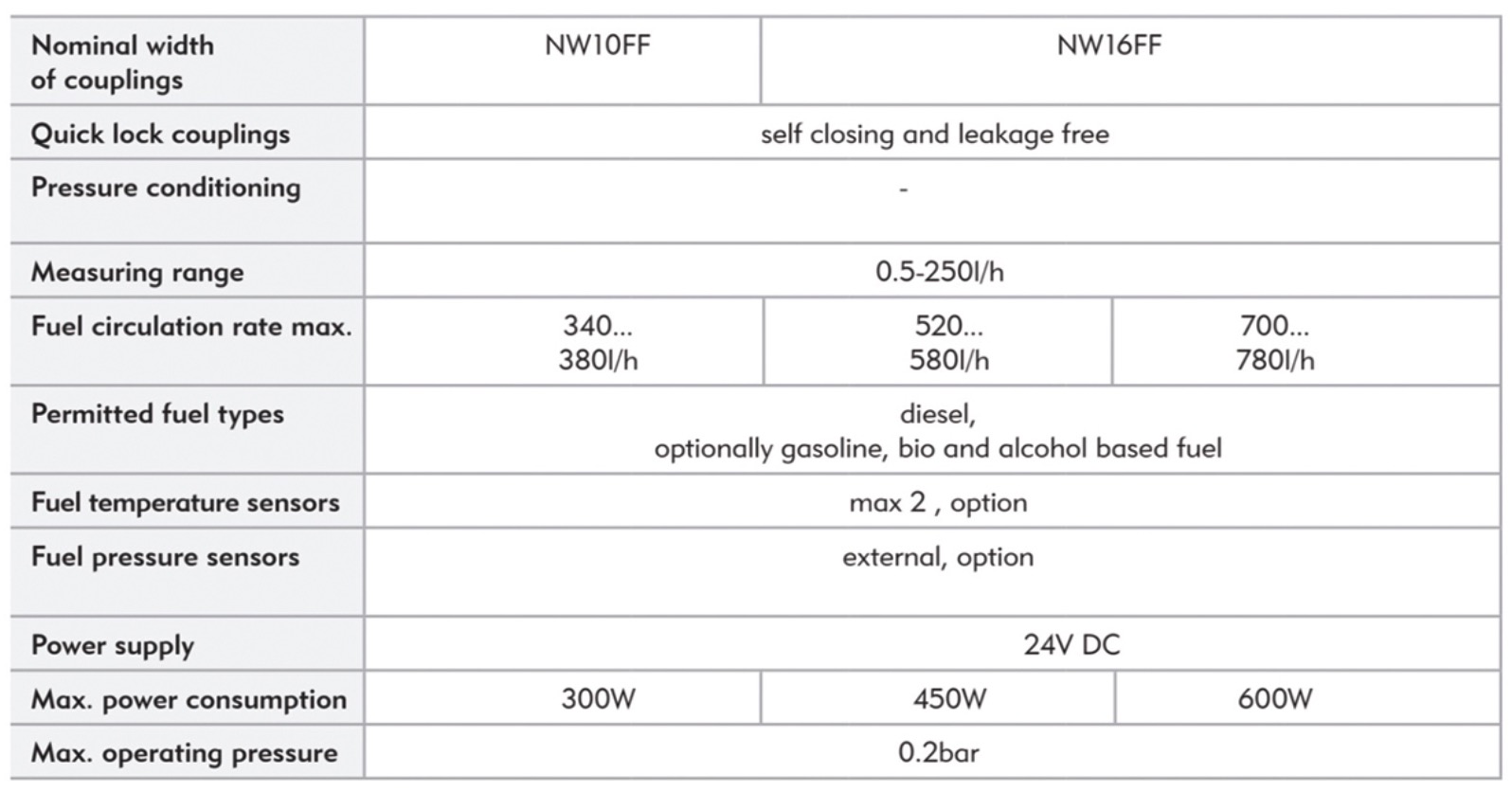

System selection table(FCS-D)

Technical parameters(FCS-D)