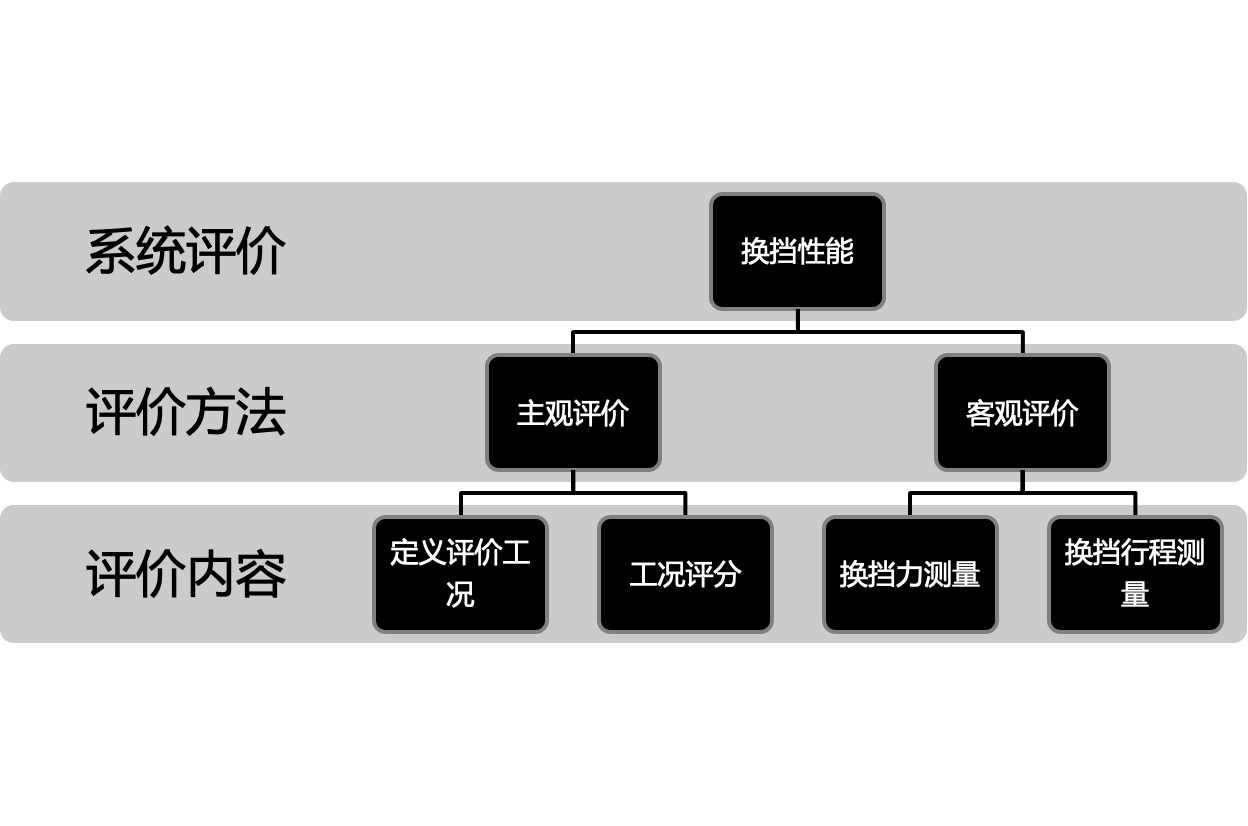

Shift performance test system

Contents of subjective evaluation of shift performance

Typical operating industrial control:

Evaluate under different ambient temperature conditions, such as engine high temperature or low temperature environment, etc.;

Evaluate under different transmission conditions, such as idle speed and driving conditions

Upshift or downshift operation at a fixed engine speed point

Sport driving mode or Comfort driving mode

Typical subjective evaluation characteristics:

Force: selection, shift force level and characteristics; forward and return travel characteristics, viscous characteristics, limit characteristics, etc.;

Stroke: select shift stroke, whether adjacent gears overlap, shift track consistency, gear identifiability

NVH: Whether the gear is vibrating or making abnormal noises

Overall performance: Shift stuck, gear accuracy, etc.

Shifting performance objective evaluation content

It mainly includes the following evaluation items:

The engine is at a standstill (off). At this time, parameters such as shift force, shift stroke, gear position, etc. in the parking state are measured. This is mainly to evaluate the gear selection force, gear selection displacement, and idle travel of each gear under static conditions.

Engine idle (standstill) state. It mainly measures the relevant performance of the shift control mechanism under the condition of idling and starts, and focuses on the parameter information such as the control force (synchronization force), impact force (secondary impact), and gear entry probability of the starting gear.

Engine running (dynamic) state. Parameters such as shifting force, secondary shock, and synchronizing impulse of the main transmission under dynamic driving conditions. Focus on the comprehensive performance of the shifting system under the action of the gearbox.

Shift system composition

3D stroke measurement module

3D force measurement sensor

Fixed bracket assembly

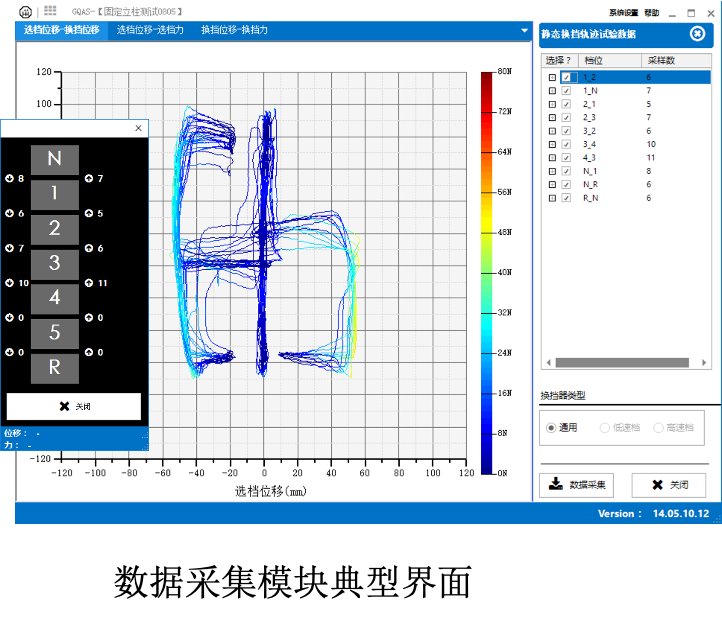

Data acquisition module

Data Analysis Module

Shift System Indicators

The system accuracy is as follows:

Measurement parameters | Measuring range | measurement accuracy | Remark |

shift displacement | 300mm | 1mm | |

shift shift | 250mm | 1mm | |

Shift lever force | 200~500N | 0.5N | |

clutch pedal stroke | 200~250mm | 1mm | Optional |

clutch pedal force | 500~1000N | 0.5N | Optional |

System basic functions

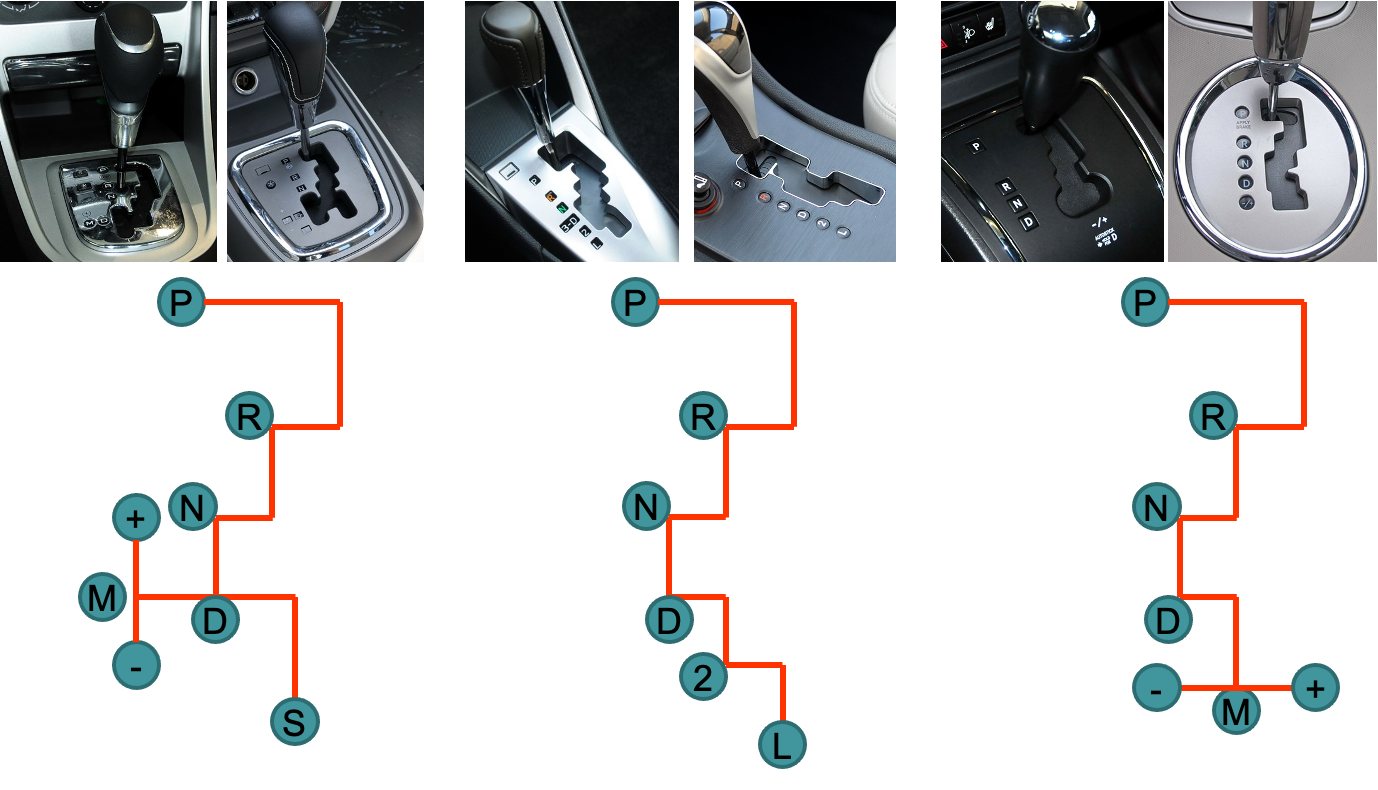

Supports various manual and automatic shifter types for measurement

Basic System Functions (Continued)

1. It can measure the manual shifter types of various gear types

Support various manual gears and main and auxiliary box type shifters

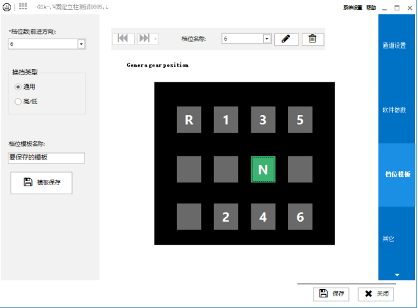

Software supports user-defined shifter modules

The created template will be saved to the system library for future use

Shifter acquisition data information is inherited from shifter template

2. It can measure the manual shifter types of various gear types

lift-up

push down

3. Data collection can be performed on various shifter planes

Adapt to various shift plane measurements

Shift planes can be entered manually and measured automatically

System software

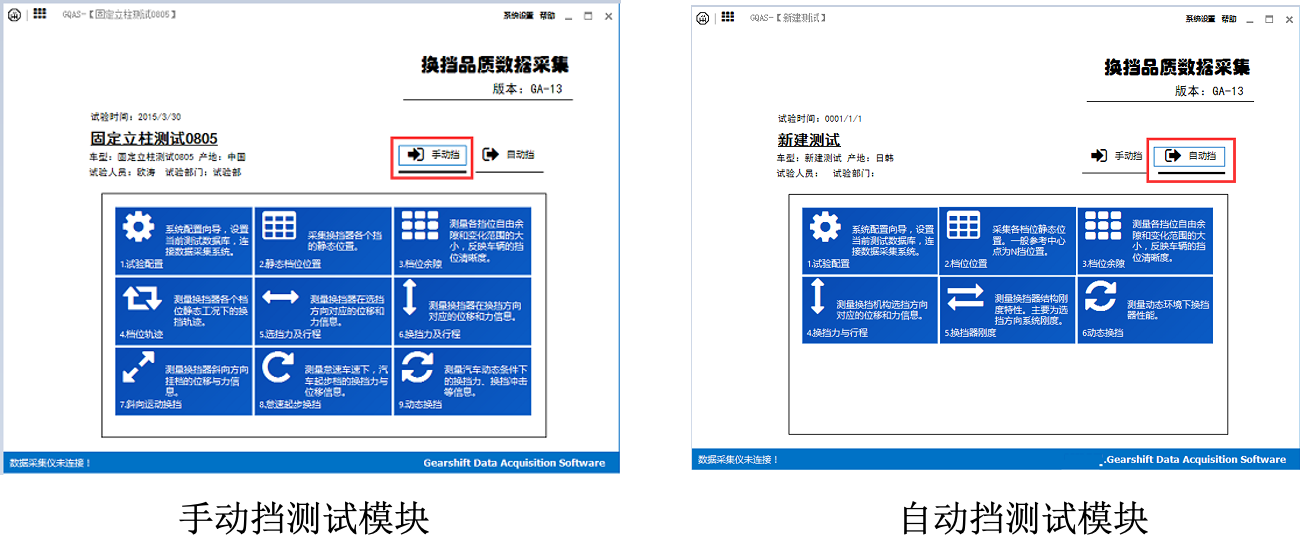

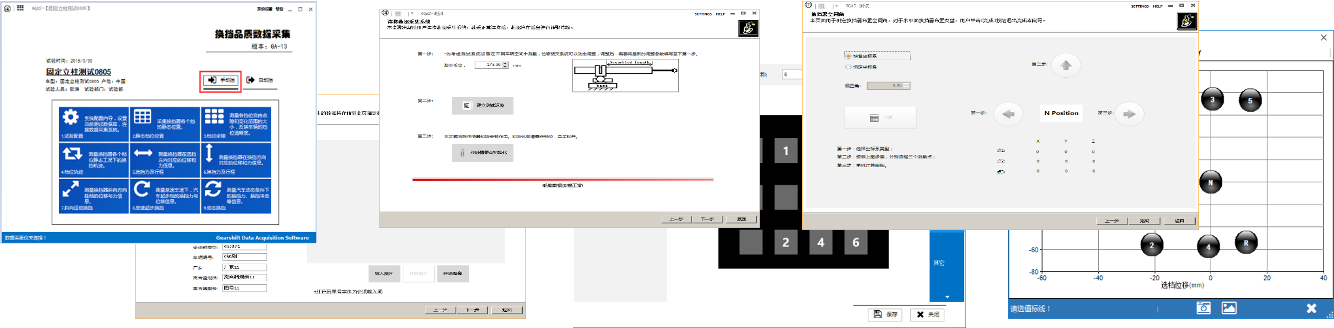

1. Data acquisition software

The main interface of the current system data acquisition software is divided into manual gear and automatic gear modules.

2. It can conveniently and smoothly complete the collection, dynamic monitoring and saving of test data

The software supports zero point calibration, and each channel can be set arbitrarily

The collected signal curve has a real-time display function, and the curve color and line type can be arbitrarily defined by the user

Process-guided operation, orderly guide the successful completion of the test

Automatic collection of shifting dynamic performance data, intelligent judgment of gear position and eligibility factors

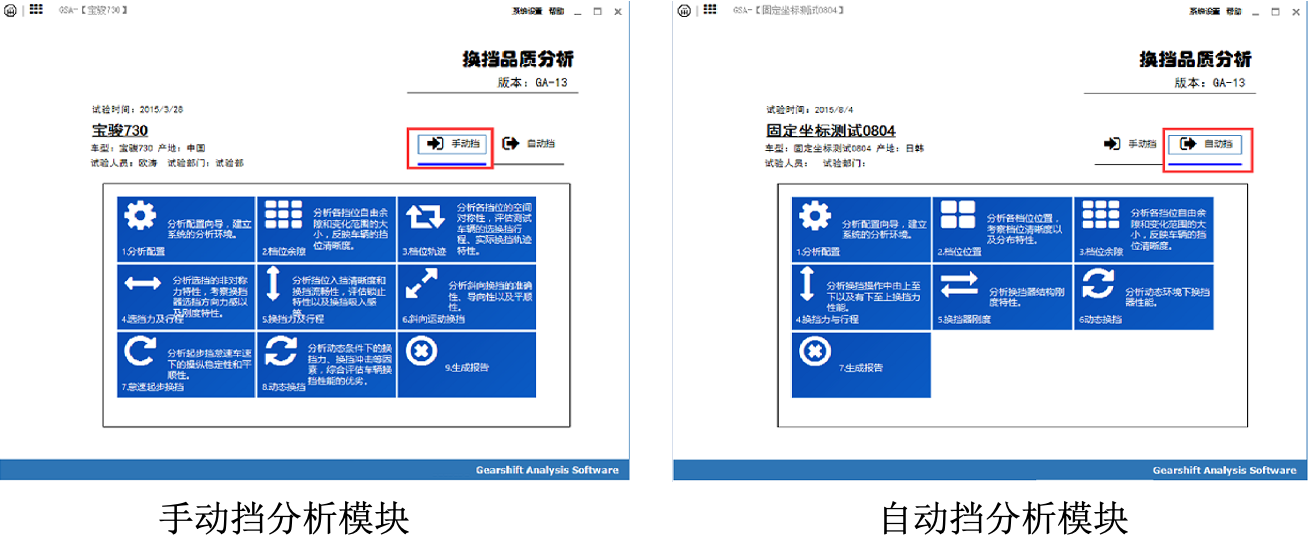

3. Data analysis software

The main interface of the current system software is divided into manual gear and automatic gear analysis modules. Each module establishes an independent analysis database.

4. Realize data processing, reporting and statistical analysis of the data collected by the test

User-friendly and highly interactive data-assisted processing functions in Chinese, which can help users obtain key performance indicators from test data

A variety of auxiliary tools help users perform chart operations. Support recipe map display.

Automatic calculation of key analysis parameters to reduce human error

System functions

1. The system includes manual transmission and automatic transmission modules

Manual transmission module

static gear position

Gear clearance

Gear track selection force and stroke

Shift force and travel

Inclined shift

Idle start shift

sport shift

Shift in comfort

Automatic transmission module

Gear position

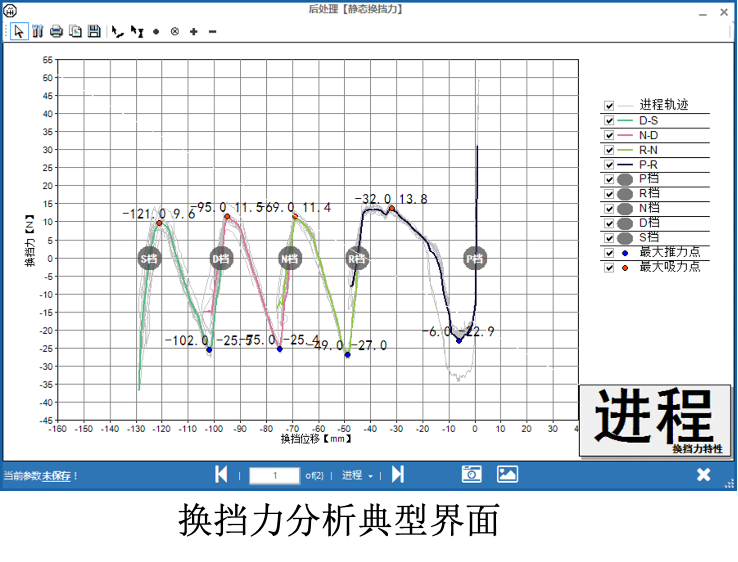

Gear clearance

Shift force and travel

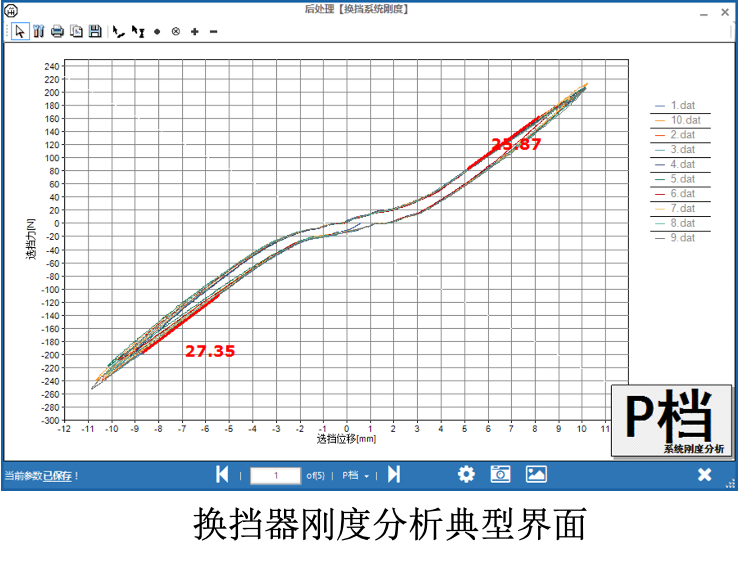

Shifter stiffness

Dynamic shifting

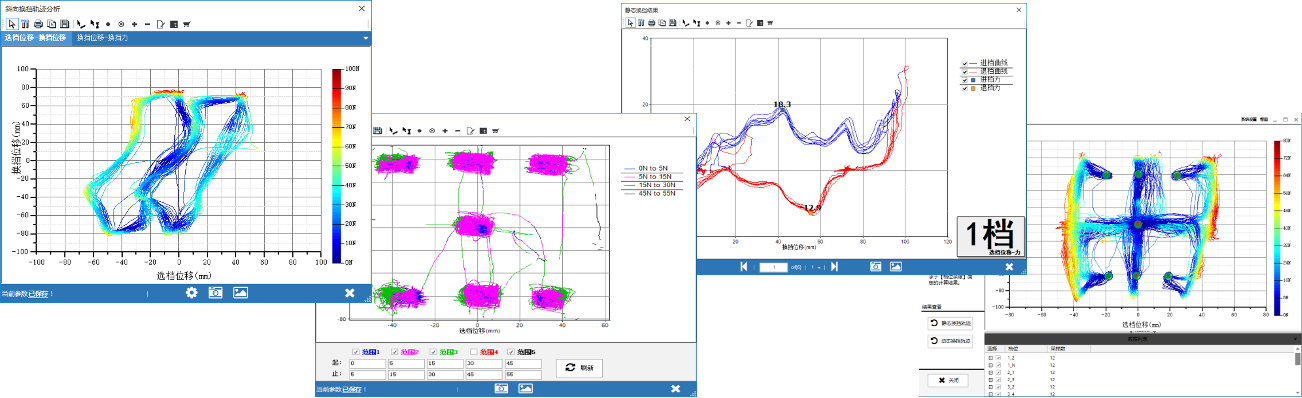

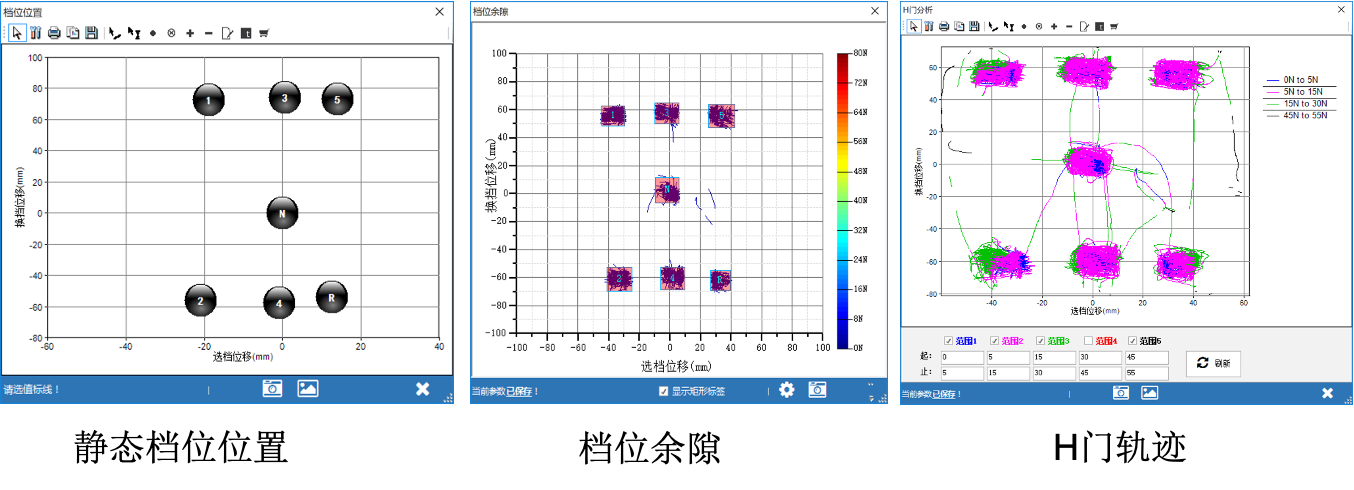

2. Gear clearance analysis (manual module)

The static gear position and gear clearance of each gear are analyzed, the holding ability of the gear position under no external force is investigated, the gear clarity of the vehicle is reflected, and the spatial symmetry of each gear is analyzed.

include:

Static gear position (planar projection)

Gear clearance

H gate trajectory

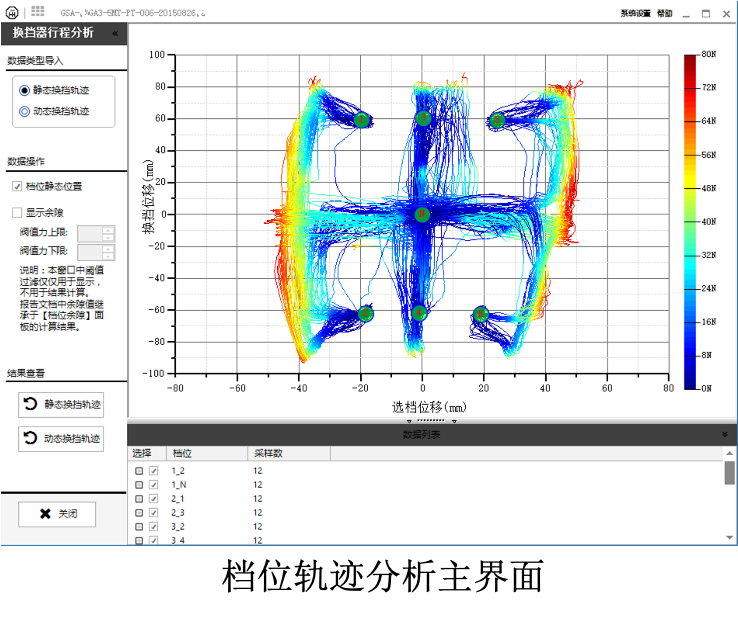

3. Gear trajectory analysis (manual module)

Analyze the gear distribution characteristics, the smoothness of the transition between gears and the spatial symmetry. By looking at the force curve, it is possible to comprehensively determine whether the overall shift force distribution is uniform and to evaluate the quality of the shift feel.

Include:

static gear track

Dynamic Gear Trajectory

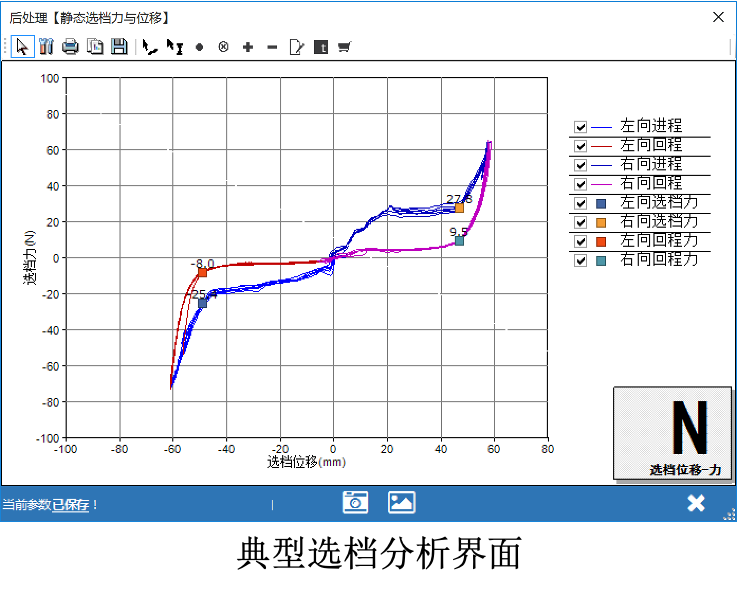

4. Gear selection displacement and force analysis (manual module)

The gear selection displacement and force analysis module mainly examines whether the curve of the gear selection process is smooth and clear, when the force of the locking pin is overcome, the resistance is gentle, and the left and right are symmetrical.

include:

Gear selection stroke

Gear selection process stiffness

Gear selection force

Gear selection hysteresis

Gear selection system stiffness

System Damping Characteristics

Select Roughness

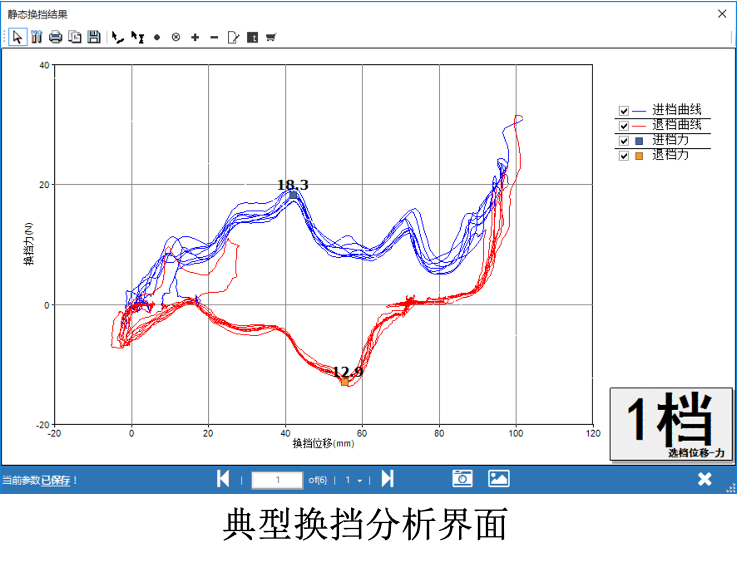

5. Gear selection displacement and force analysis (manual module)

Analyze the shifting force and shift displacement of each gear, reflect the clarity of the test gear, evaluate the characteristics of the locking pin and the shifting suction feeling, etc. By analyzing the shifting curve, it can reflect whether the characteristics such as the suction feeling and sensitive area reminder are obtained. In order to fully reflect, make an evaluation of the shifting clarity and shifting smoothness.

Include:

Average maximum gear force

Average maximum backshift force

5N corresponding stroke

Maximum gear stroke

Gear Rigidity

Suction stiffness

suction power

Backshift stiffness

Shift roughness

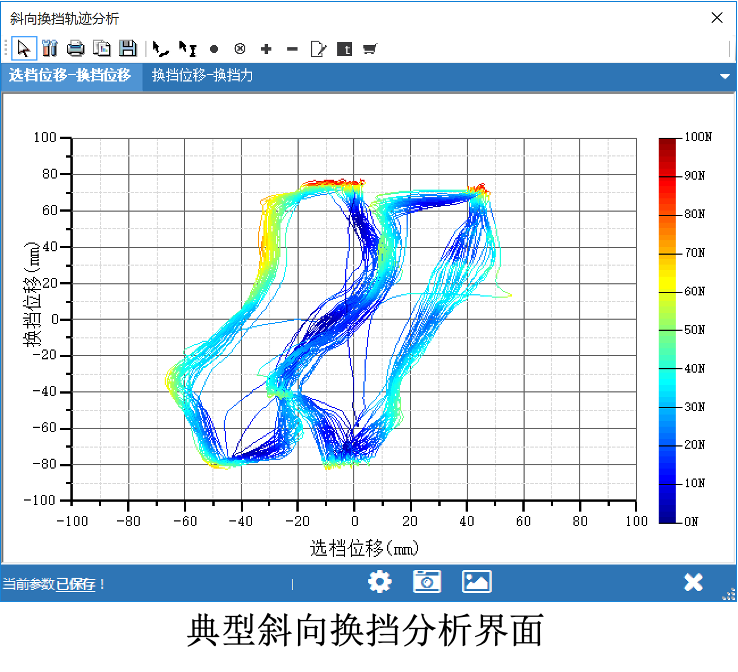

6. Analysis of oblique shift characteristics (manual module)

Mainly analyze the accuracy, guidance and smoothness of oblique shifting. Analyze the range and angle of the oblique passage of the shift lever, so as to judge whether the design of the bevel angle of the shift finger, the bevel angle of the shift fork and the bevel angle of the interlocking plate and the technological level meet the requirements.

Include:

Oblique passing range

Inbound and outbound trajectory offset

Oblique motion track angle

Select the shift stuck position

Shift roughness

Gear track consistency

peak force

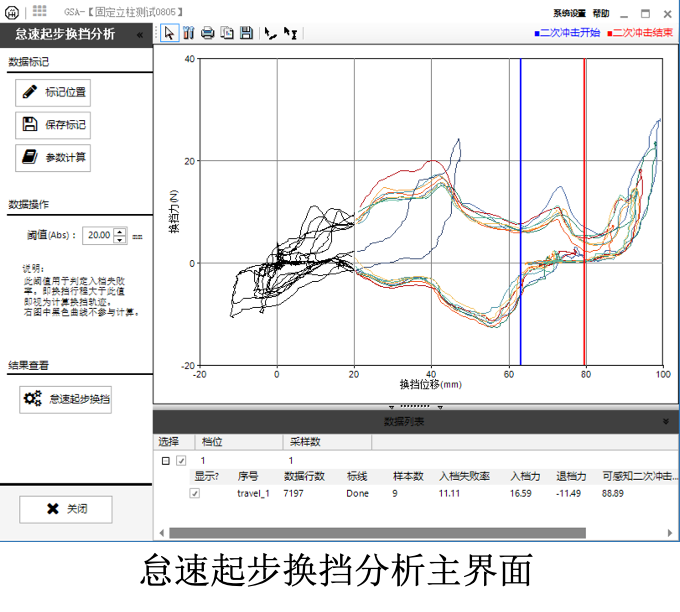

7. Idle start shift analysis (manual module)

Analyze the relative performance of the starting gear of the transmission control system under the condition of engine idling. Focus on its shifting force, maximum synchronizing force and secondary impact phenomenon. Determine the smoothness of the gear by its displacement and force curve.

Include:

Shift sample number statistics

File entry failure rate

Average gear peak force

Average back-off peak force

Perceived secondary shock rate

unacceptable secondary shock rate

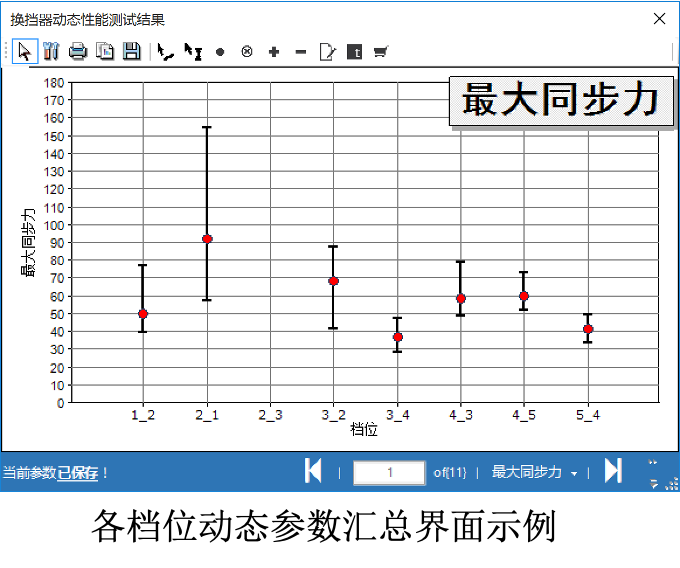

8. Dynamic shift analysis (manual module)

Dynamic shift analysis is the main evaluation of vehicle shift system, and it is a comprehensive reflection of shift performance. It is mixed with the influencing factors of the shifting mechanism and the shifting information of the synchronization performance of the transmission. By measuring the shifting force and shifting displacement during the dynamic shifting process, the division of different shifting stages, shifting force, synchronization Analysis of impulse, secondary impact, etc., to evaluate the characteristics of shifting force and shifting impact under dynamic conditions, so as to judge the pros and cons of the comprehensive performance of dynamic shifting.

Include:

maximum synchronizing force

average synchronization force

synchronizing impulse

synchronised time

Shift stroke impulse

Secondary impact impulse

secondary impact force

Li ratio

Synchronized traversal

shift time

total shift stroke

…

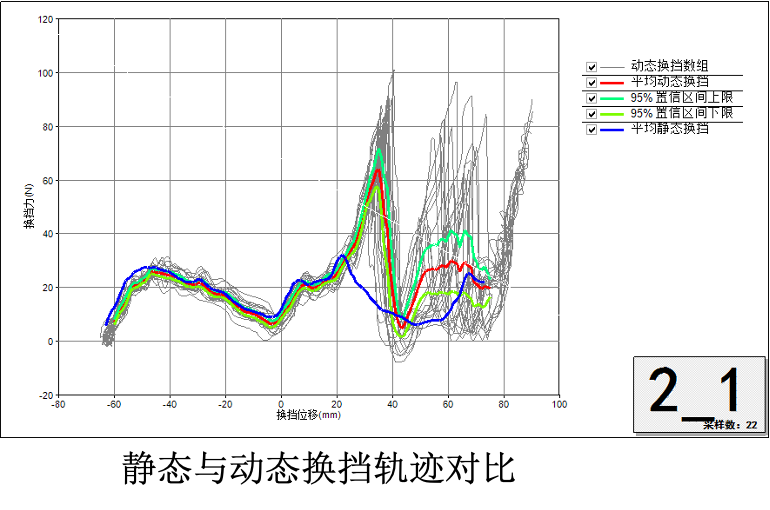

9. Dynamic shift analysis continued (manual module)

The gear shift test is divided into static and dynamic tests. The dynamic test usually means that the function of the transmission (synchronizer) is added on the basis of the static test. For this reason, it is necessary to study the function of the transmission (synchronizer) separately.

In order to achieve its purpose, the average data generated by the statistical calculation of the static and dynamic data of the gear shifter are comprehensively compared and displayed, as shown in the following figure.

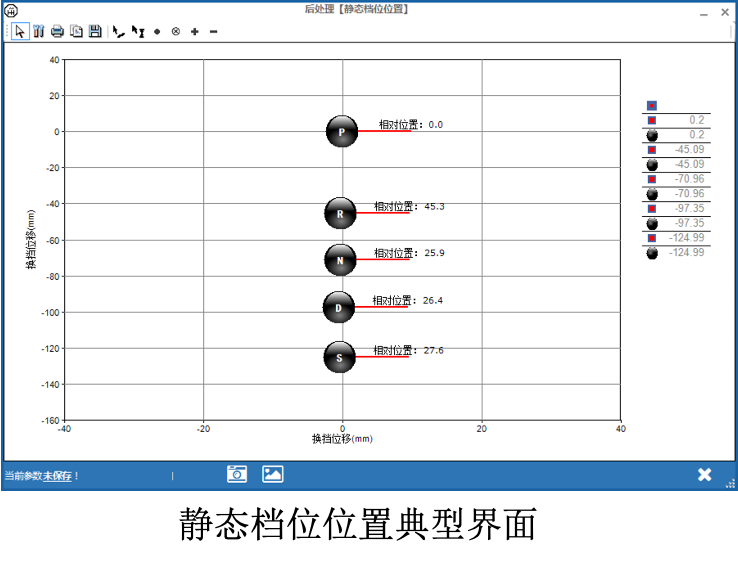

10. Static gear position analysis (automatic module)

The static position of each gear is analyzed, the distribution characteristics of gears are examined, and the arrangement of the shifting mechanism is evaluated based on ergonomics, whether it causes shifting fatigue, etc.

Include:

Gear order

gear absolute position

gear relative position

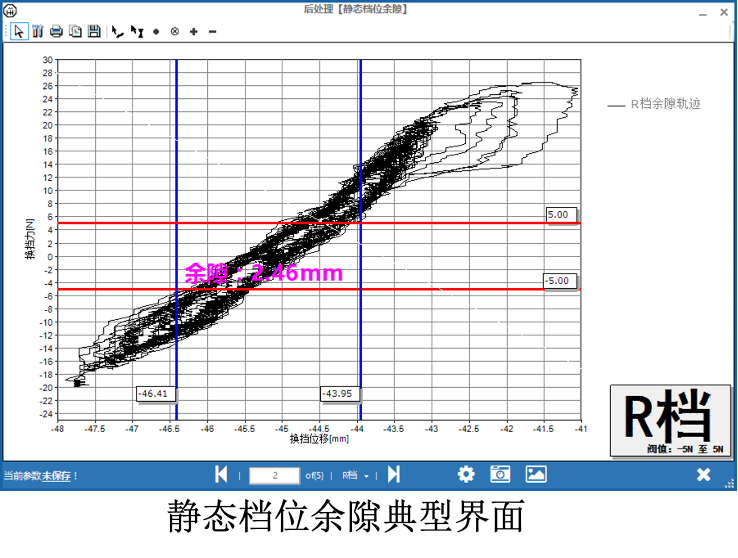

11. Static gear gap analysis (automatic module)

Analyze the static clearance of each gear, examine the ability to maintain the gear position under the action of no external force, reflect the gear clarity of the vehicle, and examine the feel of the gear shift.

include:

Gear selection to play

shift to clearance

12. Gear clearance analysis (automatic module)

The shift force and stroke of the shift lever in the static state are analyzed to reflect whether the characteristics of the shift mechanism, such as suction and sensitive area reminders, have been fully reflected. This test reflects the gear clarity of the vehicle, evaluates the locking characteristics of the operating mechanism and the feeling of shifting suction.

Include:

peak thrust position

peak thrust

Peak suction position

peak suction

maximum hysteresis

13. Gear clearance analysis continued (automatic module)

Process thrust stiffness

Process suction stiffness

return thrust stiffness

Return suction stiffness

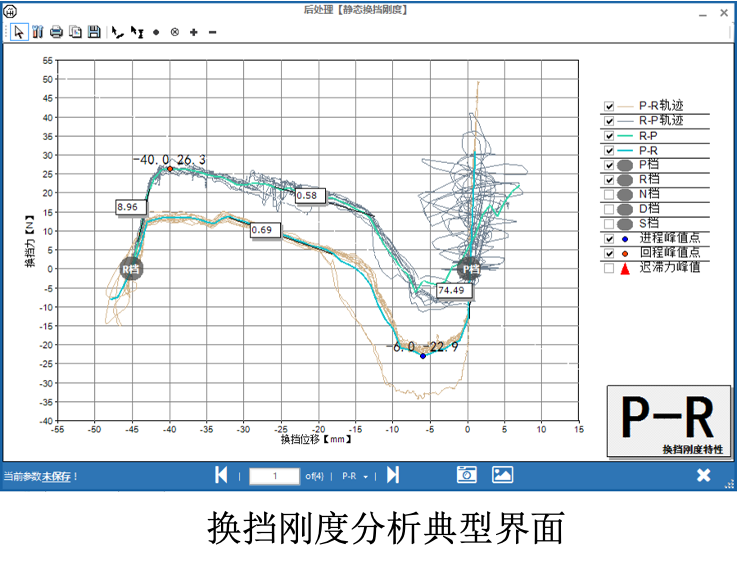

14. Static shifter stiffness analysis (automatic module)

Analyze and evaluate the reliability of its shifting function. Measure the operating mechanism assembly clearance and the free play in the selection direction.

Include:

Gear selection system stiffness

System Damping Characteristics

15. Shift performance database management

The software provides a shift database management module to realize comprehensive management of shift test and analysis data. In this module, data of any vehicle model can be viewed and analyzed, and vehicle parameters can be extracted and compared according to relevant conditions.

Software function

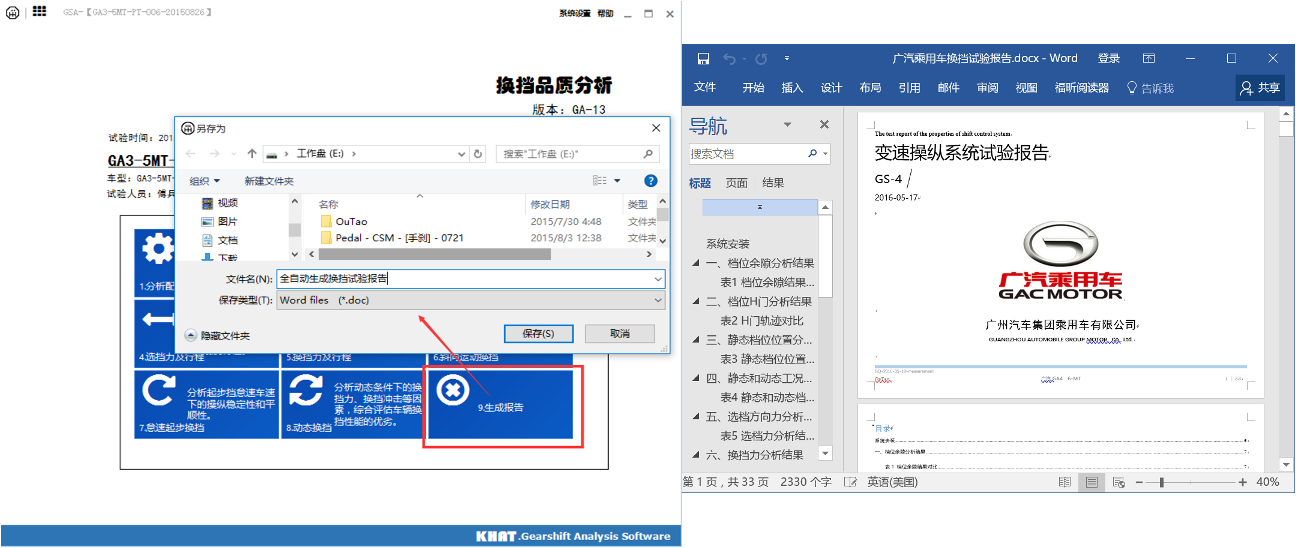

Analysis result viewing and output

Automatically solve the shifting performance data and archive it in real time;

Automatically generate a WORD version test report for the shift analysis item.

Technical Support

Flexible service, fast response and reliable partner

The same team of technology development and after-sales service is located in China, and can provide the fastest service response for Chinese customers

Customized software development according to customer requirements

Flexible combination sales of shift performance test modules and pedal performance test modules can be provided

Typical customers of the system (partly)

序号 | 系统 | 销售单位 | 交付地址 | 项目时间 |

1 | 换档踏板力集成测试设备 | 浙江吉利汽车研究院有限公司 | 临江工业区世纪大道188号 | 2011年8月30日 |

2 | 选换挡操纵性能评价系统 | 东风汽车股份有限公司 | 武汉市创业路136号 | 2012年10月8日 |

3 | 换挡质量评价系统 | 上海萨克斯动力总成部件系统有限公司 | 上海市纪鹤公路3189 | 2012年12月26日 |

4 | 换挡性能评价系统 | 东风柳州汽车有限公司 | 柳州市屏山大道286 | 2013年1月5日 |

5 | 换挡力测试系统 | 浙江科技学院 | 浙江省杭州市西湖区留合路 | 2013年6月1日 |

6 | 踏板力测试系统 | 一汽东机工离合器 | 长春市西新经济技术开发区东风大街5762号 | 2013年6月13日 |

7 | 汽车挂档测试仪 | 中国重汽山西大同齿轮 | 山西大同云州街99号 | 2013年8月9日 |

8 | 踏板力行程测试系统 | 广汽研究院试验中心 | 江东工业园区江东四路6188号 | 2013年12月30日 |

9 | 换挡性能评价系统 | 四川现代汽车有限公司 | 四川省资阳市雁江区现代大道 | 2014年1月10日 |

10 | 换挡性能评价系统 | 江西五十铃汽车股份有限公司 | 西省南昌市新建县璜溪大道19号 | 2014年4月4日 |

11 | 换挡性能测试系统 | 重庆长安汽车股份有限公司 | 重庆市江北区 | 2014年12月5日 |

12 | 变速及离合操纵品质评价系统 | 一汽解放青岛汽车有限公司 | 青岛市李沧区娄山路2号 | 2014年12月10日 |

13 | 换挡性能评价装置 | 广汽研究院 | 江东工业园区江东四路6188号 | 2014年12月24日 |

14 | 换挡及踏板品质测试系统 | 江西昌河铃木 | 江西省景德镇市新厂东路208号 | 2015年3月13日 |

15 | 汽车换挡性能检测系统及离合性能检测系统 | 重庆力帆乘用车有限公司 | 重庆市渝北区金开大道1539号 | 2015年5月15日 |

16 | 变速操纵特性测试系统 | 第一汽车股份有限公司技术中心 | 吉林省长春市创业大街1063号 | 2015年7月2日 |