ADAS test solution

Many mainstream cars are now equipped with advanced driver assistance systems (ADAS), and testing such systems requires special equipment and capabilities, often including the ability to control the relative position of the cars. With the priority recommendation of EuroNCAP (European New Car Safety Assessment Association) and NHTSA (National Highway Traffic Safety Administration) to be equipped with this technology to warn drivers of impending collisions, our robots have been widely adopted around the world and serve as First choice for ADAS testing.

ADAS test common requirements:

1. Can you follow a predetermined path with centimeter-level accuracy?

2. Precisely control the speed of the vehicle so that it follows the set speed curve?

3. Can you brake with a fixed deceleration?

4. Precisely control the relative distance between the two vehicles in the X and Y directions?

5. Is it possible to trigger a specific event when multiple conditions are met?

ABD solutions:

1. Path following----The path following function of the robot system can guide the vehicle to travel along a predetermined path with a control accuracy of 2cm at a speed of up to 220km/h.

2. Vehicle speed control----Provide a series of pedal robots to accurately control the speed of the vehicle, and the speed control error is less than 0.5km/h (depending on the quality of PID adjustment).

3. Precise braking-----Using a braking robot or CBAR, the stable and precise braking input required for automatic emergency braking (AEB) and forward collision warning (FCW) tests can be achieved. A range of control modes are available, including pedal stroke, pedal force and vehicle deceleration control.

4. Relative position control between vehicles - For many types of ADAS development and testing, precise synchronization of more than one vehicle is the key.

We provide many solutions for vehicle synchronization: (1) Longitudinal distance control: VBOX ADAS or RT Range; (2) Simultaneous horizontal and vertical distance control: Sync mode.

5. Settable trigger conditions—for example, when one or two trigger conditions are satisfied at the same time, or when the trigger conditions are met and remain for a period of time, the preset event will be executed.

Achievable ADAS tests:

◆ AEB test----EuroNCAP regulations;

◆ FCW front collision warning;

◆ Crossroad collision warning;

◆ Seat belt tensioning----caused by rear-end collision;

◆ NHTSA brake test procedures;

◆ Automatic parking system test;

◆ Pedestrian safety;

◆ Lane change assistant decision-making system---ISO1738;

◆ ACC adaptive cruise control----Cut in/Pull out test—ISO15622;

◆ AEB test - C-NCAP procedures;

◆ LDW lane departure warning---ISO17361 and NCAP;

◆ LKA, LSS lane keeping system test;

◆ BSD blind spot detection system test;

◆ AES automatic emergency steering system test.

We also offer a range of controllable soft target systems that can be synchronized with robotic or human-driven vehicles to reduce the risk of damage to test vehicles during ADAS testing.

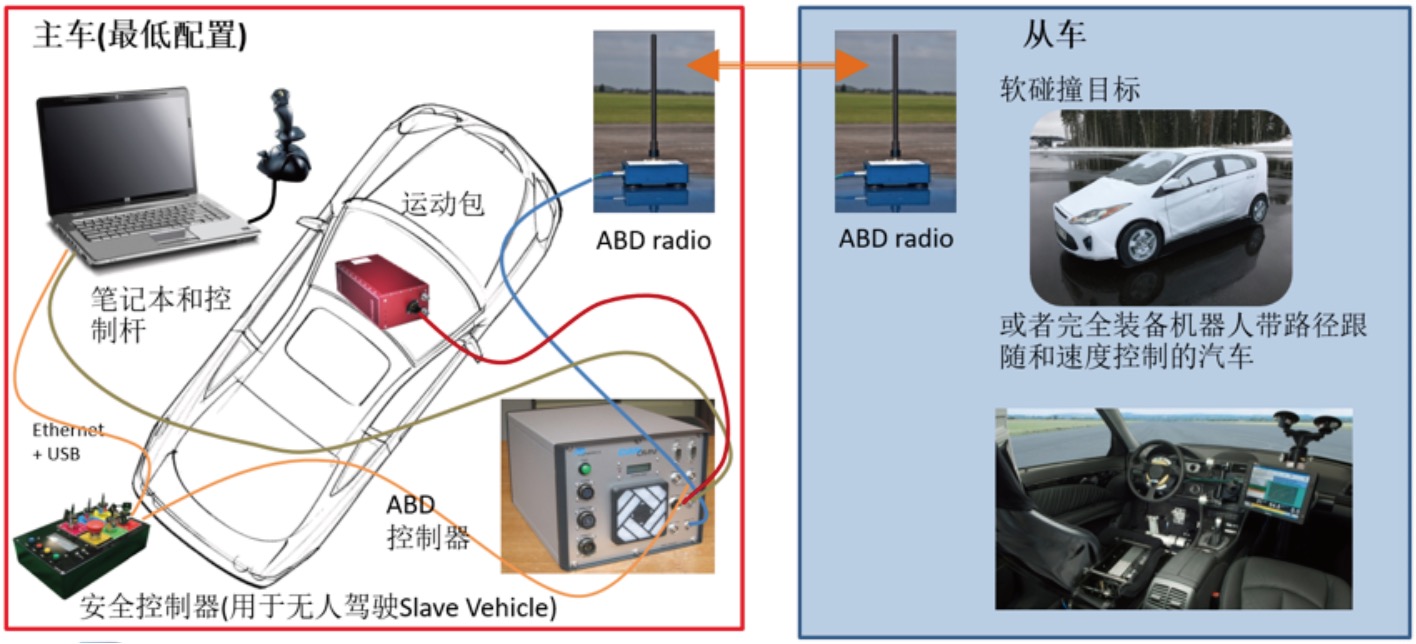

Minimum setup equipment for ADAS Testing

Guided Soft Target

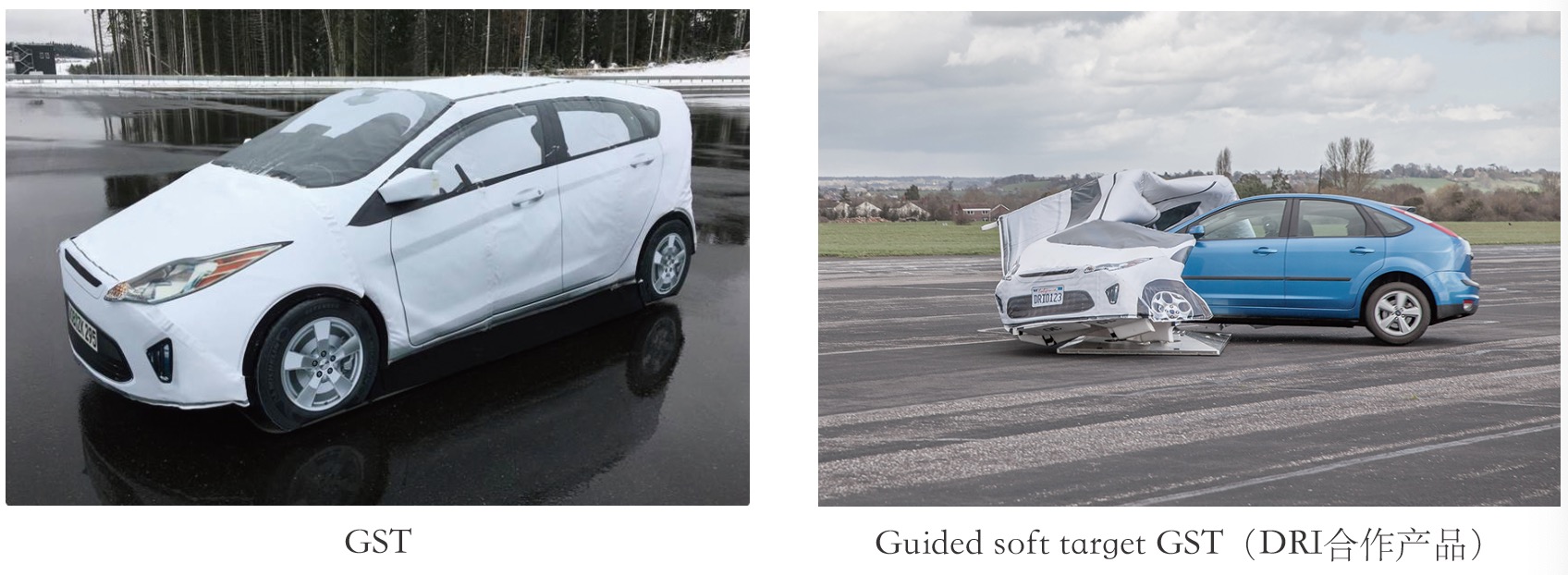

The Mk2 Guided Soft Target Vehicle ( GST ) is a next-generation platform designed for vehicle Advanced Driver Assistance System (ADAS) testing. The Mk2 GST has all the advanced features of the first-generation GST design, while still having an extremely low 100mm height. This guided soft target vehicle is a collaborative product between us and Dynamics Research Ltd ( DRI ). This product combines DRI's rolling platform concept with our leading path following and synchronous control technology.

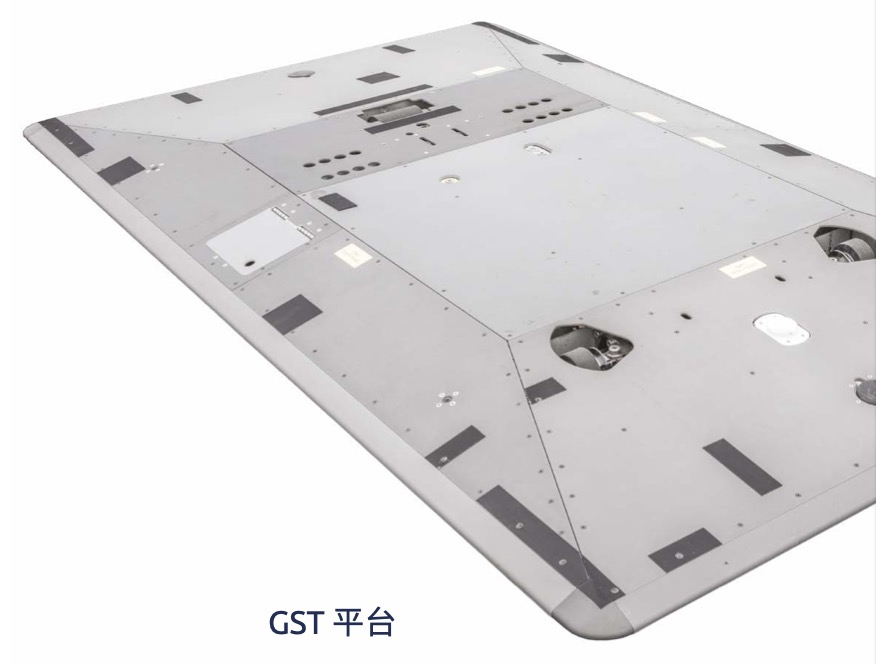

The guided soft target vehicle (GST) was designed so that a high-speed crash could be achieved without significant damage to the test vehicle. It consists of a low profile chassis (LPC from which the vehicle can be rolled) and a detachable foam panel body (the Soft Car 360 harmonized Global Vehicle Target, GVT). As the test vehicle rolled over this low-profile vehicle, the wheels retracted into the undercarriage to protect the GST's suspension and minimize possible shock to the test vehicle's suspension.

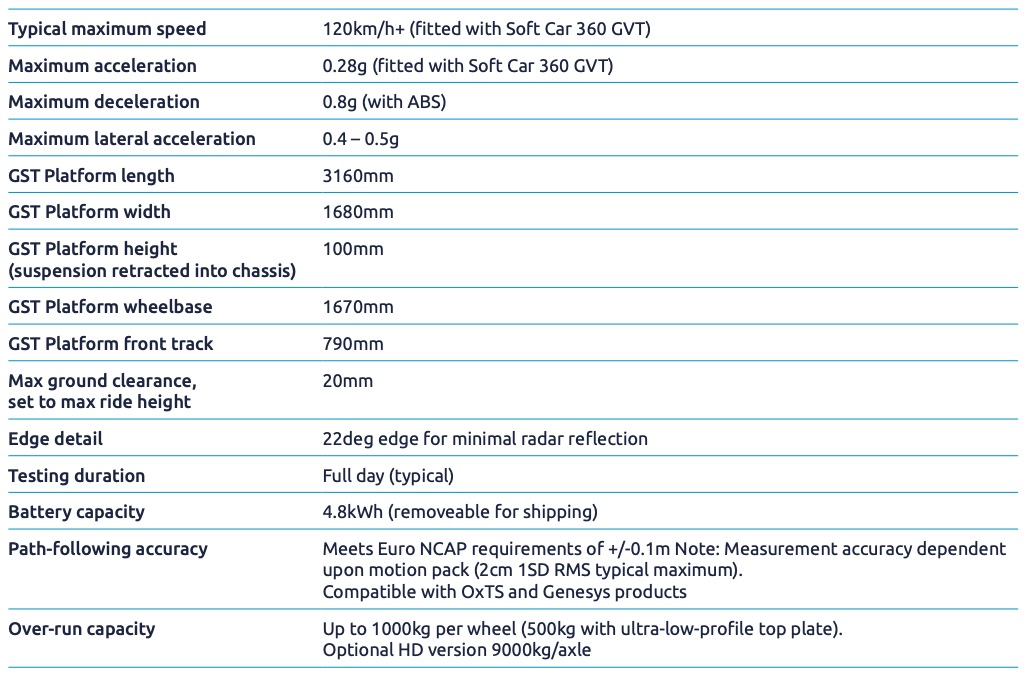

GST Guided Soft Target | GST100 | GST120 |

| Maximum acceleration | 0.22g | 0.28g |

| Maximum deceleration | 0.8g | 0.8g |

| Maximum lateral acceleration | 0.4-0.5g | 0.4-0.5g |

| Low profile chassis (LPC) mass | 315kg | 345kg |

| LPC Length | 2950mm | 3160mm |

| LPC Width | 1680mm | 1680mm |

LPC Height (suspension retracted into chassis) | 100mm | PL100mm |

| LPC Wheelbase | 1400mm | 1670mm |

LPC Front track | 790mm | 790mm |

| Max ground clearance | 20mm | 20mm |

| Edge Detail (for minimal radar reflection) | 22deg | 2deg |

| Battery capacity | 3.6KWh | 4.8KWh |

| Path-following accuracy | 2cm | 2cm |

| Over-run capacity | over 1000kg/wheel | over 1000kg/wheel |

| Maximum speed | 100km/h | 120km/h |

Guided Soft TargetTM 120 (GST 120TM)

GST 120 is currently the most powerful target vehicle system available for testing advanced driving assistance systems (ADAS) in automobiles. The maximum speed of GST 120 can reach 120km/h, which is the only product in the market that can test the highway auxiliary system and auto drive system on the real highway.

The initial GST design of GST 120 shares many leading features with AB Dynamics and is widely used in Euro NCAP testing. Thanks to its height of only 100mm, it can operate at speeds of up to 120km/h and is equipped with a class leading 4.8kWh battery.

GST 120 can conduct high-speed collision tests without causing serious damage to the test vehicle. It consists of a GST platform that can be driven from above and a separate foam panel body (GVT, the global vehicle target of the Soft Car 360 harmonized standard). When the vehicle passes the platform, the wheels will retract into the chassis to protect the suspension of the platform and generate as little impact input as possible on the suspension of the test vehicle.

By using an electric motor with an onboard battery to propel the vehicle, the control system of the GST platform can accurately guide the vehicle along a pre programmed route at a specified speed. The batteries used to power the system will provide sufficient power for a typical day of testing, and during testing intervals, they can also be connected to a suitable power source for easy charging.

The controller will use the position feedback provided by the high-precision GPS calibrated inertial navigation system to achieve precise path following control. The time signal provided by GPS devices will be used to ensure precise millisecond level synchronization, which is essential for precise and repeatable collisions and close range passing scenarios.

GST can be controlled through the radio of the same remote base station used in the AB Dynamics standard unmanned driving test system. By using the same system as AB Dynamics' robots, GST can be used simultaneously with other vehicles to create complex multi vehicle testing scenarios. AB Dynamics' mature path following and synchronization control technology enables seamless integration of the GST 120 with all existing AB Dynamics track testing products.

LaunchPad

LaunchPad is a compact power platform designed to carry road Vulnerable User (VRU) soft targets for vehicle ADAS development and testing. It has a top speed of 50km/h and full path following capability and is suitable for pedestrian, bicycle and motorcycle models. Compatible with synchronous system and synchronous mode, it can realize synchronous test with test vehicle or other ADAS test target.

| Launchpad | Launchpad 50 | Launchpad 60 | Heavy Launchpad |

Dimensions (mm) | 917mmL x 875mmW x 65mmH | 917mmL x 875mmW x 65mmH | 917mmL x 875mmW x 75mmH |

Weight (approx.) | 40kg | 40kg | 45kg |

Weather resistance | Fully sealed electronics, waterproof to IP67 | Fully sealed electronics, waterproof to IP67 | Fully sealed electronics, waterproof to IP67 |

Maximum speed | 50km/h | 60km/h | 50km/h |

Max. longitudinal acceleration (braking) | 6m/s2 | 6m/s2 | 5m/s2 |

| Payload | Pedestrian, cyclist, moped, animal. Maximum 15kg | Pedestrian, cyclist, moped, animal. Maximum 15kg | Pedestrian, cyclist, moped, animal. Maximum 15kg |

Batteries | Twin high-capacity 400wh LiFePO4 battery packs, Rapid Battery Swap system | Twin high-capacity 540wh LiFePO4 battery packs, Rapid Battery Swap system | Twin high-capacity 400wh LiFePO4 battery packs, Rapid Battery Swap system |

| Drive-over capacity | 1000kg per wheel | 1000kg per wheel | 3550kg per wheel |

| Scale size |  |  |  |

LaunchPadTM Spin

LaunchPad Spin is an ADAS target platform that elevates the operability level of VRU testing to new heights. Its ability to turn on the spot and turn with one wheel allows it to rotate 360 degrees in an instant, so your test can highly replicate the common behavior of pedestrians changing directions quickly in the real world. In addition, its maximum speed is 30 kilometers per hour, which also allows it to test scenarios related to bicycle riders and electric two wheeled bike riders.

LaunchPad Spin is an important tool to enable your development plan to leap from basic regulation testing of ADAS functions to the complex perception and classification required by auto drive system.

Technical specifications

| Size | 892 x 868 x 65 mm |

weight | 45 kg (excluding battery) |

| Maximum speed | 30 km/h |

| Maximum acceleration | 3 m/s2 (0-20 km/h) |

| Operability | Single+/-90 ° steering front wheel and independent drive motor, height controllable |

| Payload | Pedestrians, cyclists, electric bicyclists, animals, up to 15 kg |

| Battery | High capacity lithium-ion battery pack 540Wh, fast battery replacement system |

| Weather resistance | Fully enclosed electronic product, waterproof grade up to IP67 |

LaunchPad Spin is specifically designed to meet the requirements of urban testing environments.

· Upgrade the traditional belt drive system with a fully rotating platform to easily meet the UNECE testing program.

· Join the forefront of heavy commercial vehicle safety by incorporating VRU targets in challenging urban scenarios.

· Compliant with European NCAP bicycle and pedestrian testing requirements, including additional requirements for electric motorcycles and animal targets.

Soft pedestrain target

From 2016, EuroNCAP testing will include automatic emergency braking (AEB) trials with dummies instead of real pedestrians. Such trials require the use of a controllable pedestrian model that can be synchronized with the test vehicle. Our Soft Crash Pedestrian Target (SPT) uses a horizontal belt propulsion system, which eliminates the need for a high-altitude gantry (which, according to EuroNCAP, affects test results). This also makes the Soft Crash Pedestrian Target a portable system that can be quickly installed on any test track.

The soft-collision pedestrian target uses the standard steering robot motor and controller as the drive unit, and the easy-to-use RC software is used to set the soft-collision pedestrian target, which is convenient for existing robot users to be familiar with. Users can reduce the expense of the pedestrian system by using their existing steering robot (SR60 or SR60 Torus), which can be easily and quickly installed and removed from the pedestrian system. Alternatively, there is an option with a built-in dedicated motor.

Soft Pedestrain target | SPT20 | SPT205 |

External SR required | Yes – SR60 / SR60 Torus | No, built in |

| Maximum rated speed | 20 kph with 15 kg payload | 20 kph with 15 kg payload |

| Maximum acceleration | >1g with 15kg payload | >1g with 15kg payload |

| Position measurement accuracy | Uses motor encoder: : The accuracy of the motor end is higher than 0.01mm, and the dynamic accuracy is usually better than 2cm | |

| Driving power | 3.2kW | 3.2kW |

| Installation | Steering robot can be quickly converted between SPT / SR use | No extra installation required other than belt setup |

| Sled height | 25 mm | 25 mm |

System protection | In built belt tension measurement system checks belt and stops motor if belt tension changes significantly | |

| Water resistance | Can be used in rainy conditions; case acts as a rain cover for motor. Motor box sealed, suitable for wet and icy conditions. | |

Soft Pedestrian 360TM

The Soft Pedestrian 360 from DRI is the next generation of articulated surrogate pedestrian target, bringing a whole new level of realism and vehicle protection to VRU testing.

Sophisticated active articulation including upper body joints enables naturalistic movement and the ability to synchronise gait with platform speed, so that acceleration and deceleration are more realistic than ever. Additionally, the Soft Pedestrian 360's robust design has been carefully considered for repeatable, uninterrupted testing.

Available in both adult and child variants, the Soft Pedestrian 360 has been developed by the same team from DRI that brought us the iconic Soft Car 360®. The Soft Pedestrian 360 is the result of years of real-world testing experience gained working with the world’s leading OEMs and the NHTSA.

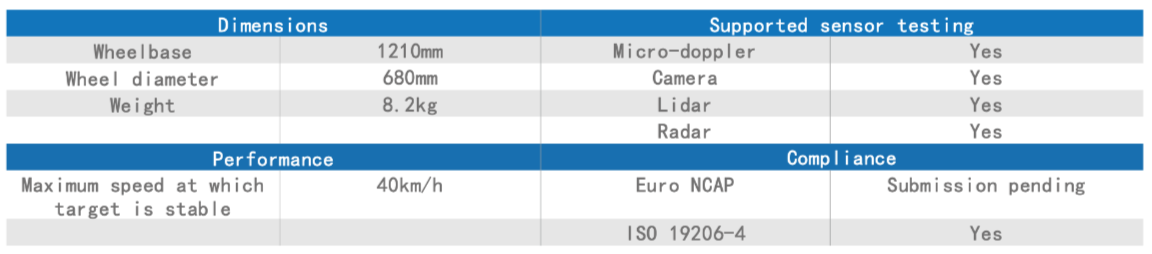

Technical specifications

Soft Motorcycle 360TM

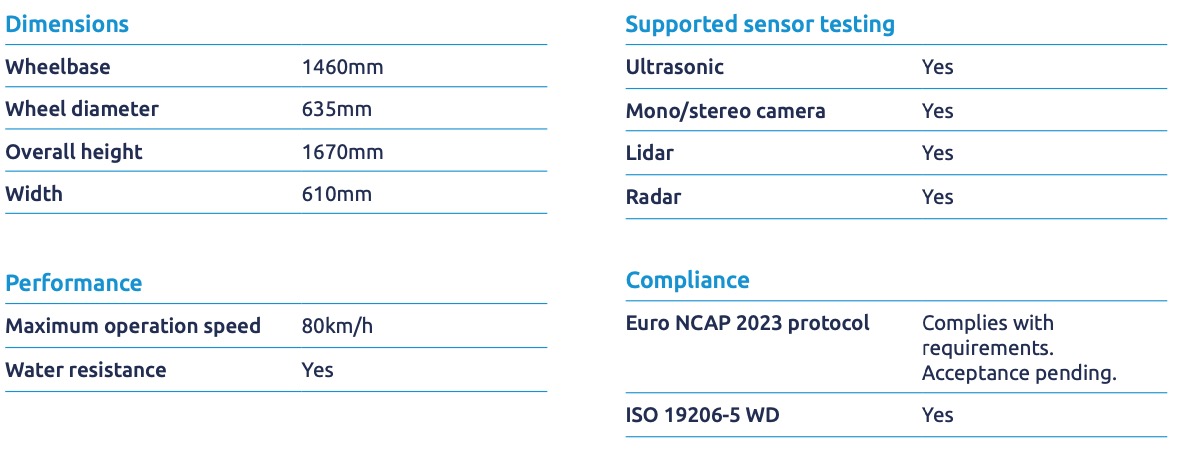

The Soft Motorcycle 360 from DRI is a durable and realistic surrogate motorcycle target that is stable at speeds of up to 80km/h. Its rotating wheels and realistic shape mean that it is reliably recognised by vehicle sensor systems including cameras, radar and lidar.

Durability is key to the Soft Motorcycle 360's design, with its lightweight foam construction minimising the potential for vehicle and target damage. Plus its modularity means that when parts are damaged they can quickly and easily

be replaced.

Developed by the same team from DRI that brought us the iconic Soft Car 360TM, the Soft Motorcycle 360 is the result of years of real-world testing experience gained working with the world’s leading OEMs and the National Highway Traffic Safety Administration (NHTSA).

Technical Specifications

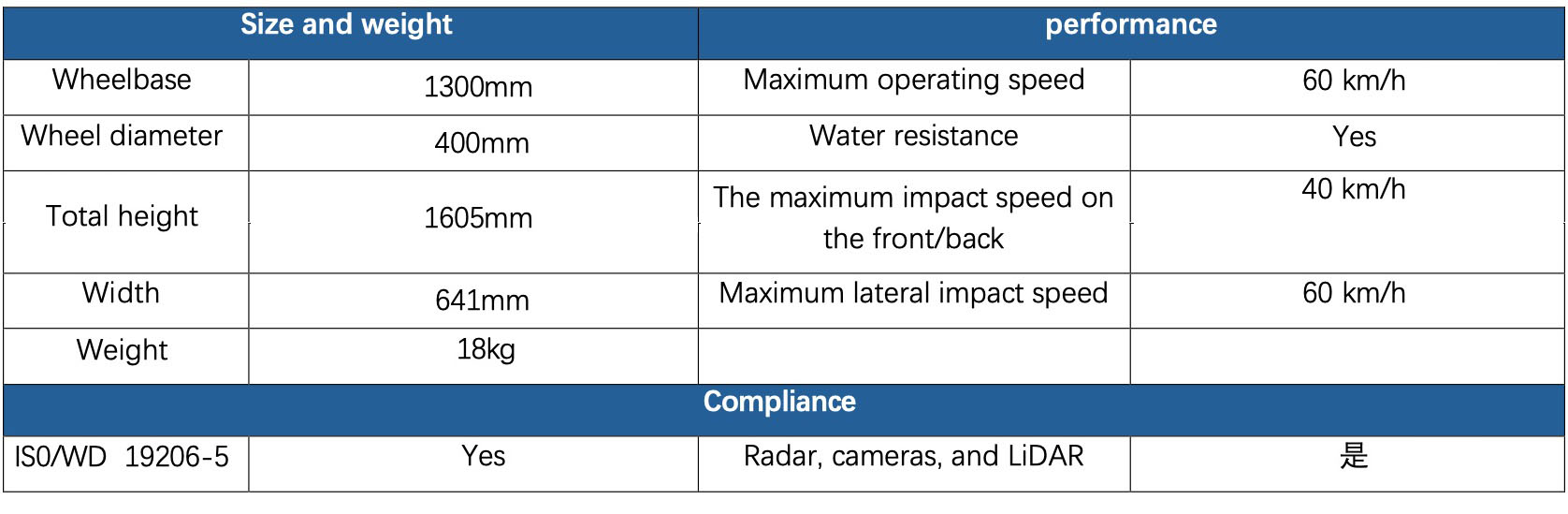

Soft Scooter 360TM

The 360 soft two wheeled vehicle is a highly realistic and economical alternative to two wheeled vehicles, with a stable speed of up to 60 km/h. The realistic appearance, matching wheel rotation rate with vehicle speed, and realistic vinyl skin all increase the recognition and detection of the vehicle's sensor system (including cameras, radar, and LiDAR).

The key to designing a 360 soft two wheeled vehicle is to focus on reducing damage to the test vehicle. To achieve this goal, the framework of the target vehicle is surrounded by tubular lightweight foam, and hard spots are minimized. The rider and scooter are separated independently, reducing potential damage.

To help improve the repeatability of your testing process, the 360 soft two wheeled vehicle adopts a modular design, which means that components are easy to replace, and each unit is also equipped with a separate spare parts kit to reduce downtime.

Technical specifications

Soft Bicycle 360TM

As regulatory bodies such as Euro NCAP expand scenarios involving cyclists, the need for a reliable and innovative

ADAS bicycle target has never been greater.

The Soft Bicycle 360’s design focuses on realism and minimising damage to vehicles under test. Recognised as a

real bicycle by sensing technologies including camera, radar, and lidar, it is also compact, lightweight, and robust. The

Soft Bicycle 360 increases test efficiency and uptime so you can conduct more tests without interruption.

Providing unrivalled stability in straight lines and cornering, the Soft Bicycle 360 is perfect for current testing requirements and is ready to replicate more challenging future scenarios.

Flex-0

Flex-0 provides a compact solution for controlling the actuators of the vehicle itself via CAN or wire-by-wire. The Flex-0 uses a software suite that can be used to perform a variety of standard tests without the need for a driving robot in the vehicle, and to achieve path following and synchronization. The controller communicates with the vehicle via the CAN protocol, a control interface that is only possible through cooperation between us and the original equipment supplier (OEM). We provide a standard CAN control protocol that the customer can convert into a format recognizable by the vehicle. Even, we can customize control protocols for customers. The Flex-0 can also be used in a driverless test system ( DTS ), allowing testing to be performed without a driver in the vehicle.

| Flex-0 | Specifications | |||

| Weight | 3kg | |||

| Dimensions | 380×220×65 mm | |||

| Data acquisition frequency | User selectable up to 2 kHz | |||

| Digital input/output | Scanning frequency 4kHz | |||

| Analog input (8 channels) | 24-bit resolution at 4kHz sampling frequency | |||

| Power input | 9-18 V DC (12V recommended) | |||

Capture+Review

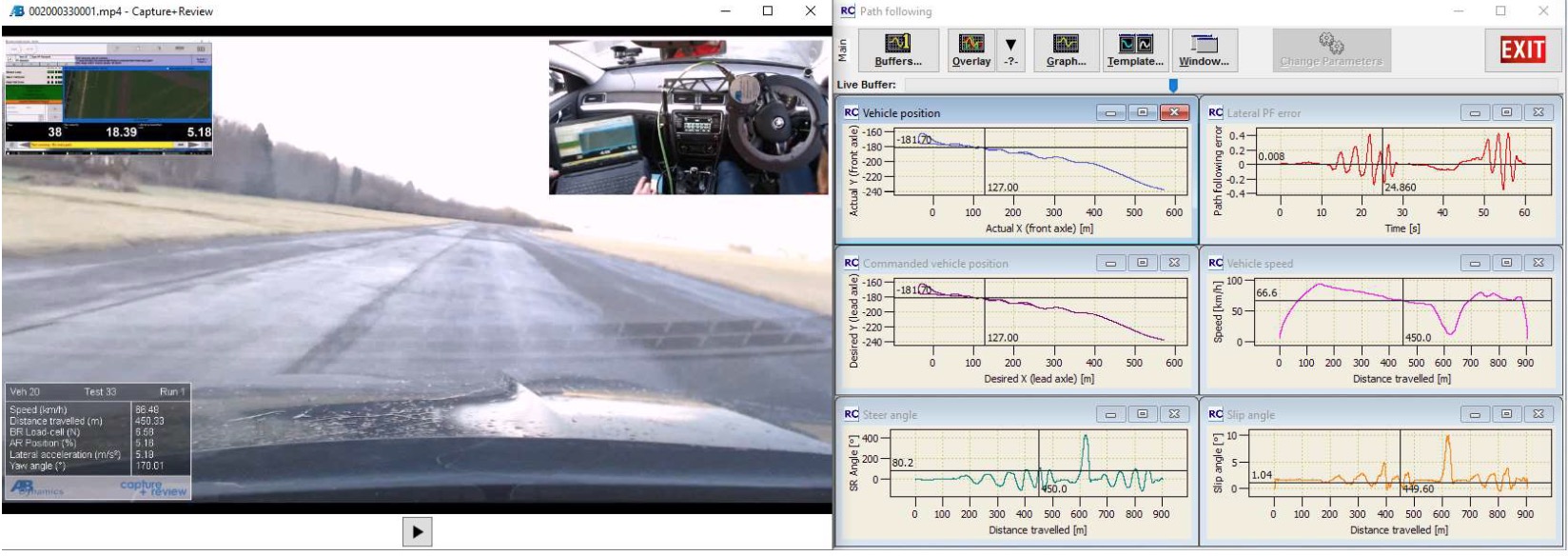

Capture+Review provides an integrated video capture solution for vehicle testing. Video can be recorded from up to four cameras or computer-integrated cameras and can be overlaid with the data channels of our driving robots. The video can be embedded in the recorded data synchronously without the need for subsequent synchronization processing by the user.When playing back the test data graph, the test video can be played back synchronously with the data.

Capture+Review is a system of USB cameras and software modules that can be used with all robot controllers. The system comes standard with two high-definition (1080p) USB webcams and a mounting fixture for in-vehicle installation.

Overview

1. Can be used with all robot controllers;

2. Customizable video superposition, receiving up to four signal sources (independent camera or computer-integrated camera);

3. Allow users to synchronously overlay the selected data channel and video;

4. Accurate evaluation of auxiliary vehicle or ADAS performance;

5. Provide perfect video and data basis for vehicle testing.