Introduction to ripple testing scheme for high-voltage components

With the development of comprehensive electrification of automobiles and the imminent implementation of domestic ripple testing standards, it is urgent to test the interference and anti-interference degree of high-voltage components in electric vehicles. Zeer Automotive combines flagship products from the global market to create a complete set of ripple testing solutions that meet the international standard ISO21498 and testing standards of major OEMs, providing customers with ideal, high-quality, and practical solutions.

Electric Vehicle High Voltage Network Diagram

1、 Ripple generation and voltage generation slope test

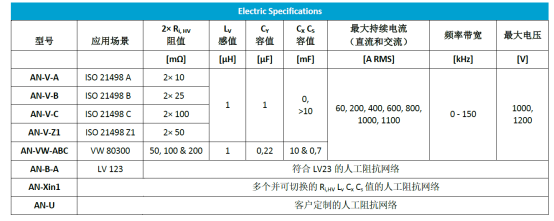

AN Series is an artificial impedance network used for component testing of B-level voltage (high voltage) components, which can electrically reconstruct the impedance of the vehicle's high voltage grid in laboratories and test benches. The use of AN Series simulation systems with a bandwidth of up to 150 kHz, and the use of AN Series artificial impedance networks for testing, will make efficiency and lifecycle testing closer to actual results, and comply with standards and internal specifications such as ISO 21498, LV 123, IEC 61851-23, etc. This is crucial for ripple generation and voltage slope generation testing of all B-class voltage components in hybrid and electric vehicles.

AN Series Artificial Impedance Network Electrical Characteristics

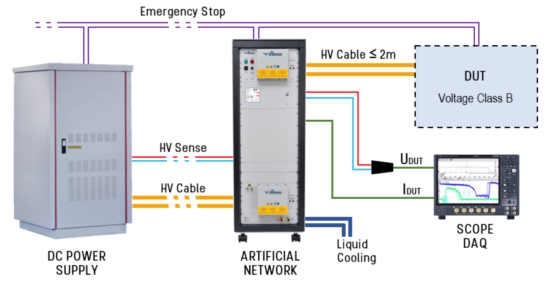

Typical application settings and layout

Typical application settings

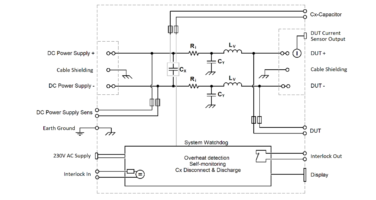

Front view of AN Series artificial impedance network

Internal structure of AN Series artificial impedance network

Advantage

1. The AN Series artificial impedance network is twice as strict as the impedance tolerance required by ISO21498. The impedance value has been calibrated by DAkkS, and a DAkkS certification certificate can be provided according to customer needs.

2. The liquid cooling scheme can ensure stable resistance temperature and constant resistance value.

3. Realizing true continuous current load without the need for load shedding, it is very suitable for online testing of high-voltage components during the development phase.

The AN Series artificial impedance network can achieve self detection and is a completely safe and reliable system.

5. Not only can the design meet the requirements of LV123, ISO 21498, and IEC 61851-23 standards, but specific solutions can also be customized according to customer internal standards.

6. A single device can integrate multiple artificial impedance networks.

2、 Ripple anti-interference test

Ripple NX is a cutting-edge solution designed to meet the needs of the electric vehicle industry. This solution provides custom ripple testing that complies with industry standards such as ISO21498-2, ISO7637-4, LV123, MBN11123, and VW80300. This system allows testing devices with voltages up to 1000V and currents up to 1000A, and can generate powerful ripple interference signals of up to 160Vpp and 1000App.

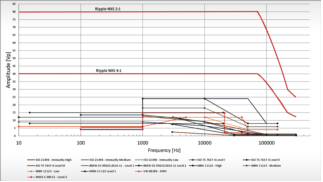

The above figure shows the ripple amplitude defined by various standards. The RIPPLE NX specifications clearly exceed these requirements, providing greater flexibility for higher testing levels and compensating for voltage drops in connecting cables.

One of the biggest challenges when testing ripple in electric vehicle components is to find the correct combination of high testing levels and impedance characteristics for projects such as batteries and inverters. The ripple current must be sufficiently large at lower frequencies or resonance points to achieve the necessary testing level. Meanwhile, at higher frequencies, high EUT impedance can lead to significant voltage drops in the connecting cables, requiring a high test voltage to compensate.

For the Ripple Generator RIPPLE NX, this state-of-the-art device utilizes a 5 or 10kw high-power amplifier and adjustable transformer ratio to optimize system configuration to adapt to high currents or voltages. This unique combination enables it to achieve the highest testing level of ISO21498 even on the most demanding high-voltage components, such as large batteries and inverters.

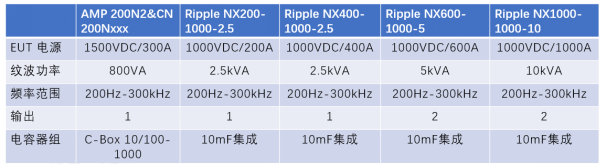

Product specifications

Typical application settings and layout

Installation diagram for battery pack immunity test

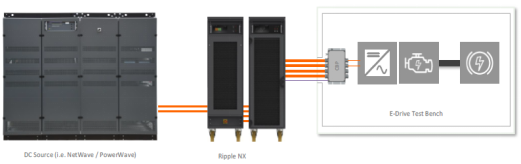

Installation diagram for electrical drive immunity test

Advantage

1. Optimize and adjust components to ensure maximum system performance and security performance

2. Specialized signal generation, measurement, and control units can achieve faster adjustment time

3. Frequency selective measurement algorithm suppresses the ripple generated by the tested inverter

4. Minimize internal wiring, making it easy to set up in different testing settings

5. By using a junction box, the EUT connection is simple and clear

3、 Overall supporting plan

Netwave (High Voltage AC/DC Power Supply)

Main features

1. Wide power bandwidth: DC-5kHz

2. Output power up to 108KVA AC/150kW DC

3. Output up to 3x690VAC (p-p), ± 1120VDC

4. High surge current capability

5. Power recovery to rated power (optional)

6. Built in signal waveform generator

7. Standard test routines for IEC/EN, Aircraft, MIL-STD, DO-160, and EV testing

8. Provide multi-source options (upgradeable)

Powerwave (High Voltage AC/DC Power Supply)

Main features

1. 250kVA/kW, can be upgraded to 1MVA/1MW

2. EV vehicle testing ECER10

3. EV high-voltage component testing

4. 1500VDC/1000A and 360VAC/236A

5. 4-quadrant operation with 100% source/destination and power recovery function

6. 1000Hz bandwidth and 1250V/ms voltage swing rate

7. Remote control and rich testing library

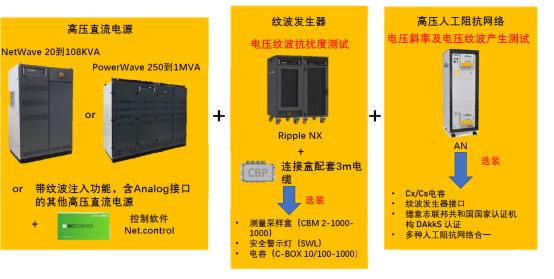

Overall supporting plan

Meet the test requirements in ISO21498:

For more product related information, please feel free to inquire about Guangzhou Zeer Testing!