Safety First, Validation as the Foundation: A Comprehensive Analysis of Safety Testing for Pure Electric Mining Dump Trucks

In the previous issue on performance testing, we conducted an in-depth analysis of the challenges faced by pure electric mining dump trucks in terms of powertrain performance, energy consumption, braking, and related aspects, along with Zeer Testing’s corresponding solutions. In this issue, we shift our focus to another core pillar—safety testing.

Safety is the lifeline of mining vehicles. For pure electric mining dump trucks operating under high voltage, heavy loads, and complex working conditions, electrical safety, structural safety, and functional safety are of paramount importance. With the release and implementation of Technical Requirements for Pure Electric Off-Road Mining Dump Trucks (GB/T 45051-2024) and Test Methods for Pure Electric Off-Road Mining Dump Trucks (GB/T 45054-2024), safety test items now span multiple dimensions, including high-voltage insulation, waterproofing and fire protection, warning and alarm functions, as well as visibility and protective measures. Leveraging years of technical expertise in vehicle testing and data acquisition, Zeer Testing provides precise, reliable, and systematic support for safety testing, helping manufacturers build a robust safety foundation.

Safety Test Items and Zeer Testing Solutions

1. Driving Sound Warning Test

Audible warning functions during vehicle operation directly impact on-site safety. We provide the ASec system or Zeer acoustic and visual warning system to ensure that driving sound alarms meet standard requirements and are clear and easily recognizable.

2. Electromagnetic Compatibility (EMC) Testing

Pure electric vehicles feature highly complex electrical systems, making EMC performance critical to overall vehicle stability and safety. Using the Zeer EMC Steering Wheel Test System, electromagnetic compatibility validation can be carried out for key components such as the steering system.

3. Noise Testing

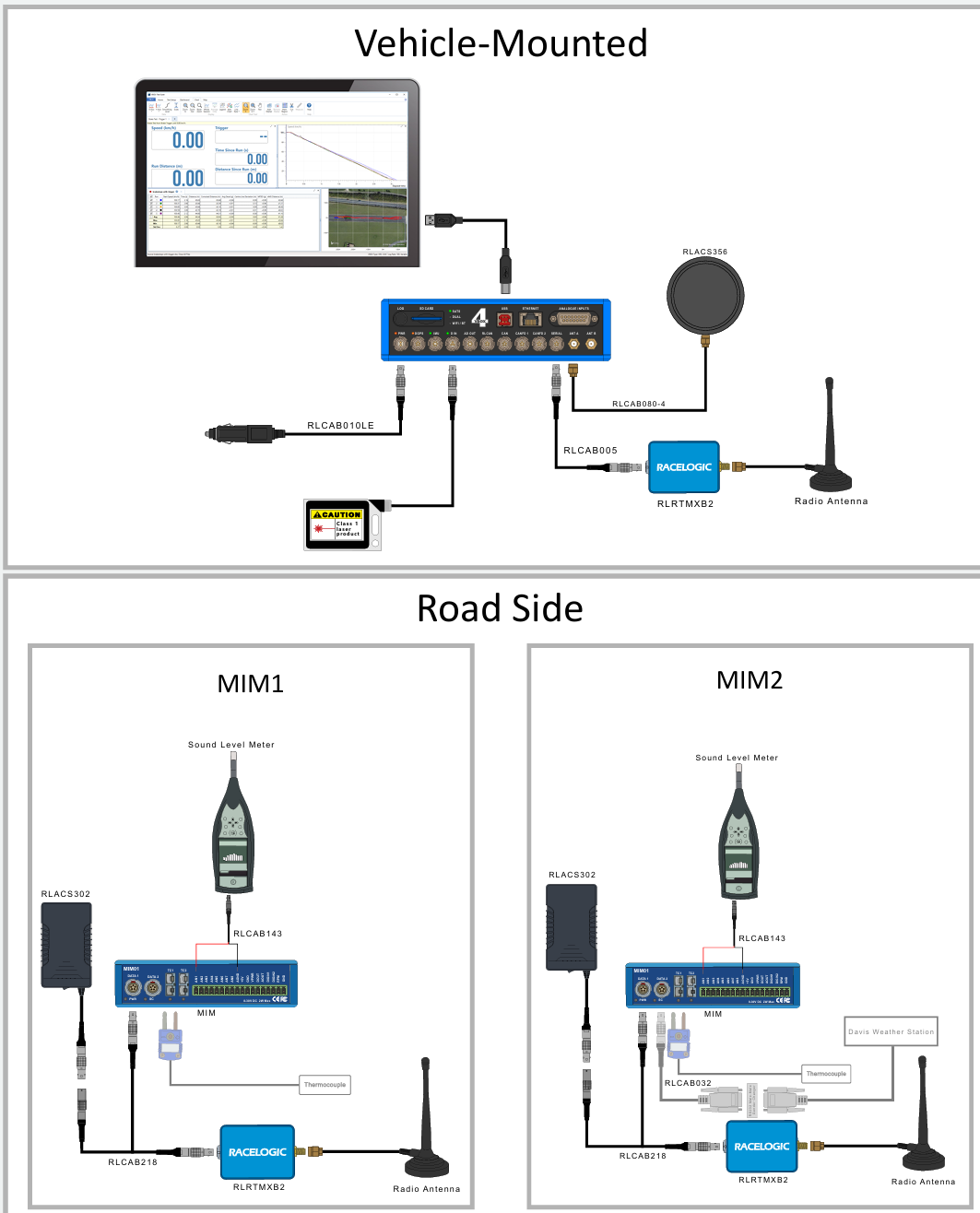

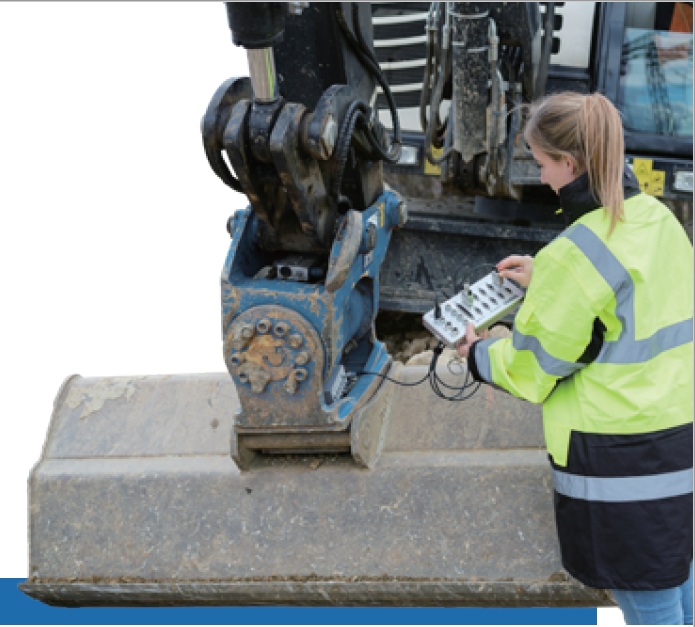

To evaluate the in-cab acoustic environment, we support the integration of sound level meters with DEWETRON or VBOX systems, enabling precise measurement of sound pressure levels at the driver’s position as well as overall vehicle sound power levels, ensuring compliance with environmental and occupational health standards.

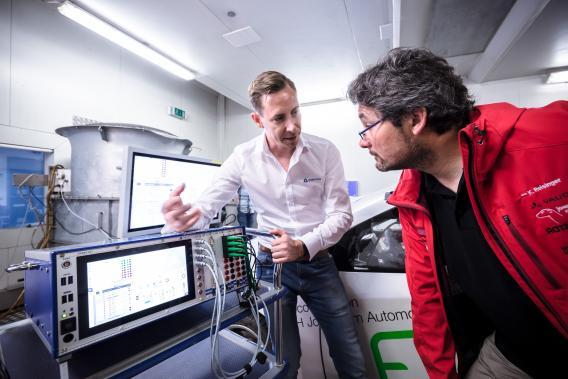

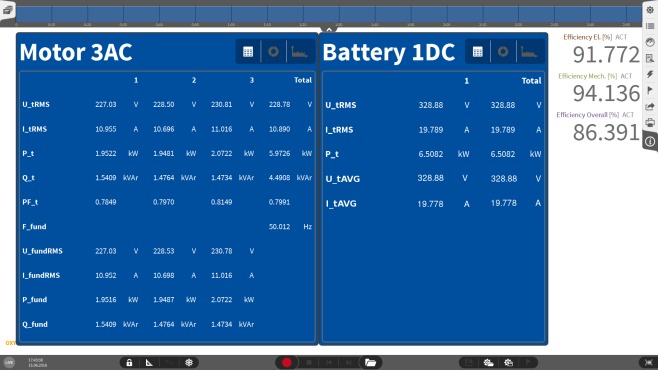

4. Insulation Resistance and Potential Equalization Testing

High-voltage electrical safety is a top priority for pure electric mining dump trucks. The DEWETRON multi-channel data acquisition system, equipped with insulation resistance measurement modules, enables real-time monitoring of the vehicle’s high-voltage insulation status and verification of potential equalization, ensuring grounding resistance meets regulatory requirements.

5. Simulated Washing and Waterproof Testing

Considering the dusty and water-intensive environments in which mining dump trucks typically operate, we provide IPX5 waterproof testing equipment. Combined with DEWETRON, insulation resistance can be continuously monitored under water spray conditions, validating the waterproof reliability of the entire vehicle and battery system.

6. Regenerative Braking Energy Recovery Limitation Alarm Test

Timely alerts are critical when abnormalities occur in the regenerative braking system. By using DEWETRON to monitor energy recovery parameters in real time, the system can automatically verify whether alarm functions are triggered promptly, ensuring the effectiveness of safety mechanisms.

7. Support for Other Safety Test Items

For additional safety-related tests—including flame retardancy, safety labeling, lighting and signaling, driver field of vision, and rollover protection—we can provide flexible support solutions such as sensor integration, data logging, and coordination with third-party test organizations, tailored to customer requirements.

With systematic, high-precision, and scalable testing capabilities, Zeer Testing comprehensively covers all aspects of safety testing for pure electric mining dump trucks—from high-voltage electrical systems to mechanical structures, and from functional verification to environmental adaptability—providing solid data support to ensure vehicle safety compliance.