Benchmarking the New National Standards: A Comprehensive Analysis of ZEER’s Performance Testing Solutions for Pure Electric Mining Trucks

With the release and implementation of the national standards Technical Requirements for Pure Electric Non-Road Mining Dump Trucks (GB/T 45051-2024) and Test Methods for Pure Electric Non-Road Mining Dump Trucks (GB/T 45054-2024), the standardized and regulated development of pure electric mining dump trucks (hereinafter referred to as “pure electric mining trucks”) has entered a new stage.

As a critical step in validating vehicle power performance, energy efficiency, and safety, performance testing places higher requirements on both test equipment and testing methodologies.

Leveraging extensive engineering testing experience and strong technical expertise, ZEER Testing provides a complete, accurate, and efficient performance testing solution for the performance test items specified in the national standards, helping manufacturers achieve compliance validation and enhance product competitiveness.

Performance Test Items and ZEER Testing Solutions

The performance of a pure electric mining truck is a direct reflection of its core competitiveness. In accordance with national standards, ZEER Testing offers professional test equipment and solutions for the following key performance test items:

1. Coastdown Test

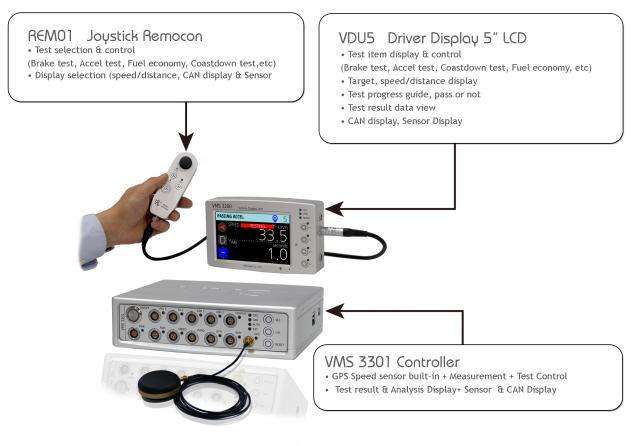

Accurate measurement of vehicle running resistance is a critical foundation for range testing on a chassis dynamometer for pure electric mining trucks. To obtain precise vehicle road load coefficients, we recommend the Infomagix VMS3301/3200C vehicle coastdown resistance test system.

This solution guides the driver to conduct tests in accordance with internationally recognized regulations, records and analyzes test data, and directly outputs accurate vehicle running resistance coefficients and curves. These results provide essential input data for energy consumption analysis of mining trucks.

As an alternative solution, the VBOX GTR15 WLTP & J2263 system can also be used for data acquisition and analysis.

2. Acceleration Performance and Maximum Speed Test

Vehicle power performance is reflected through acceleration capability and top speed. Using the VBOX test system, acceleration time and distance from standstill to 30 km/h can be precisely recorded on a straight test track, along with the vehicle’s maximum stable speed.

The system supports real-time data display and automatic generation of visualized reports, clearly presenting test results.

3. Gradeability and Power Test

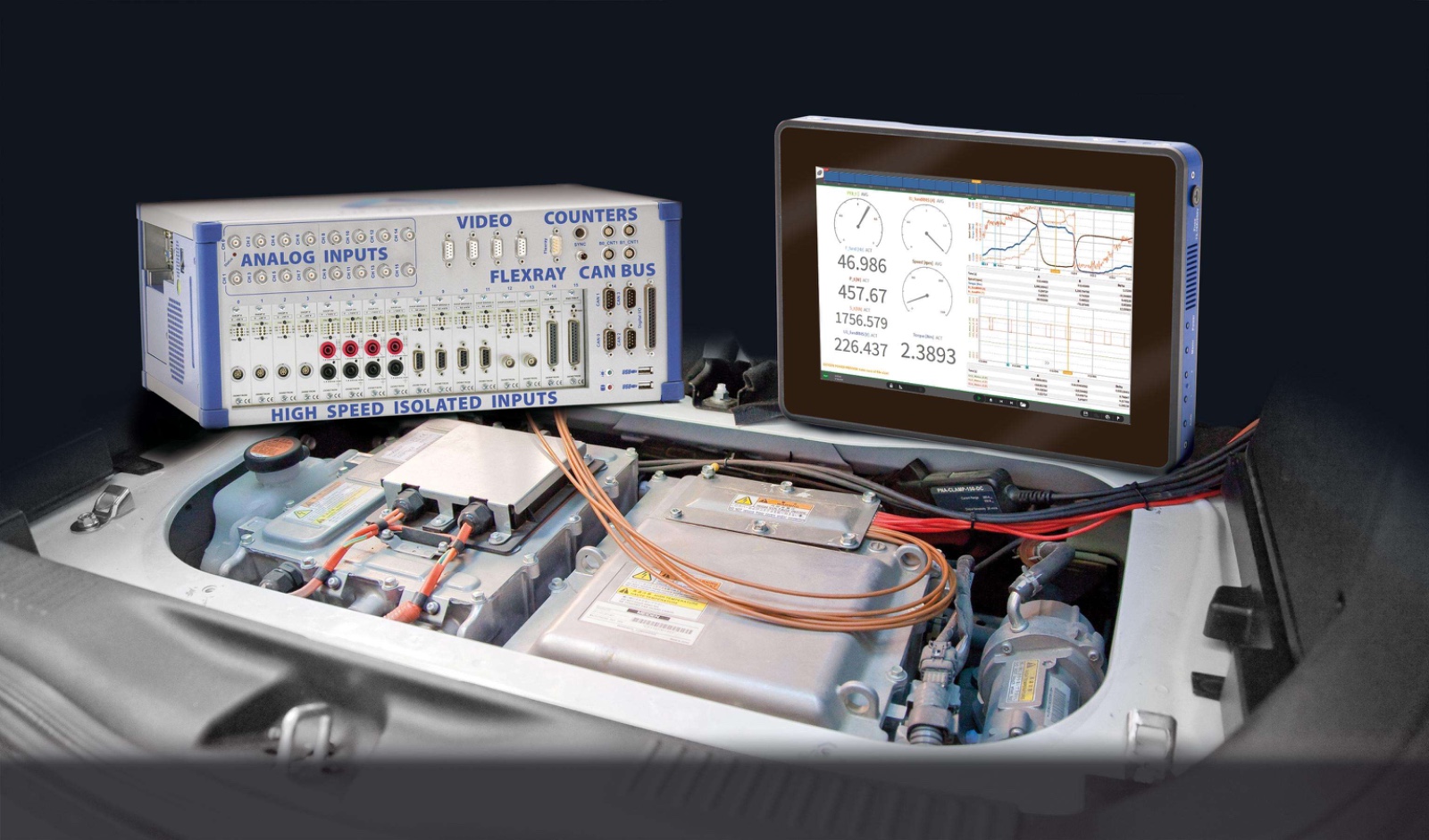

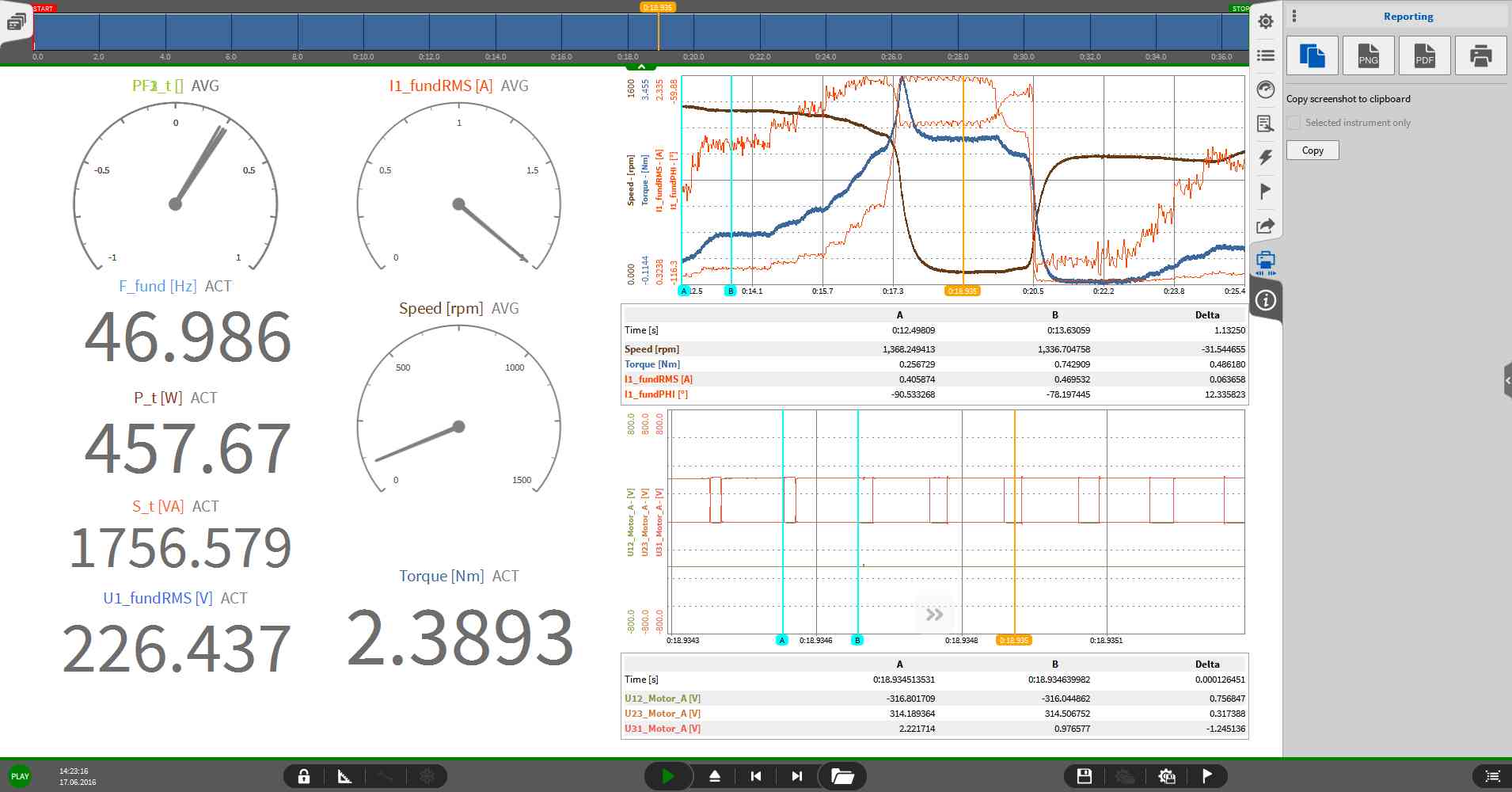

For typical operating conditions of heavily loaded mining trucks, ZEER provides an integrated testing solution. A DEWETRON multi-channel data acquisition system is used to monitor traction inverter voltage, current, and power in real time, while VBOX simultaneously records vehicle speed and road gradient.

This solution enables accurate plotting of power–time curves under real operating conditions and calculation of stable vehicle speed when climbing long gradients. For maximum gradeability verification, VBOX combined with a high-precision IMU is used to directly measure lateral slope angles.

4. Electric Braking and Mechanical Braking Test

As a key advantage of pure electric mining trucks, electric braking integrates safe deceleration with energy recovery. Through efficient synchronization of VBOX and DEWETRON systems, ZEER’s solution records deceleration and stopping distance while simultaneously capturing high-voltage DC bus data. This enables comprehensive evaluation of electric braking deceleration performance and downhill constant-speed control capability, ensuring safety and reliability of this critical function.

Mechanical braking serves as the ultimate safety safeguard. Considering the heavy loads and harsh operating conditions of mining trucks, ZEER provides a complete mechanical braking performance validation solution. Using the VBOX test system, braking distance, braking time, and vehicle trajectory can be precisely measured. In particular, the system professionally evaluates brake track deviation, ensuring stable and controllable braking direction even under heavy-load conditions.

5. Steering Performance Test

Steering controllability and stability are critical to vehicle safety. By combining VBOX with a steering wheel force sensor, steering wheel operating force, steering capability, and minimum turning radius can be accurately measured.

In addition, VBOX data can be used to evaluate steering stability and analyze wheel track retention during braking.

6. Environmental Adaptability and Energy Consumption Test

Environmental adaptability and energy efficiency are key performance indicators. Low-temperature starting performance can be verified using the DEWETRON system to record battery voltage, current, and temperature variations under low-temperature conditions.

The energy consumption rate at constant speed—one of the core economic indicators—requires high-precision measurement using a DEWETRON integrated data acquisition system with electric power analysis capability. The DEWETRON system synchronously records multi-dimensional data from the battery, motor, and vehicle, enabling comprehensive evaluation of low-temperature starting capability and constant-speed energy consumption within a single test, significantly improving testing efficiency.

7. Charging Performance Test

Charging efficiency directly affects vehicle availability and operational uptime. A DEWETRON power analyzer is used to monitor the entire charging process, recording charging voltage, current, and SOC (State of Charge) variation curves. This enables comprehensive evaluation of vehicle charging performance and provides accurate data support for optimizing charging strategies and assessing charging pile compatibility.

VBOX product information link:

https://drive.weixin.qq.com/s?k=APYAwAfcAAYR58H1TL

DEWETRON product information link:

https://drive.weixin.qq.com/s?k=APYAwAfcAAYUBgnGlA

Infomagix product information link:

https://drive.weixin.qq.com/s?k=APYAwAfcAAYvIN8aOi

With professional equipment and integrated system solutions, ZEER Testing empowers every performance validation task, ensuring accurate data and efficient testing processes, and safeguarding the development and quality of pure electric mining trucks.

In the next article, we will provide an in-depth analysis of the challenges associated with “safety” test items for pure electric mining trucks and ZEER’s corresponding solutions—stay tuned.